- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-12-26 Origin: Site

Textile machines play a vital role in the textile industry, shaping raw fibers into fabrics and garments. Without them, modern textile production would not be as efficient or consistent. In this article, we will dive into the different types of textile machines, their functions, and how they contribute to efficient manufacturing processes. By the end, you'll have a deeper understanding of their impact on textile production.

Textile machines are mechanical devices that automate various processes in fabric production. These machines handle everything from spinning raw fibers into yarn to weaving, knitting, dyeing, and finishing the fabric. By streamlining production and reducing human error, these machines help the textile industry achieve high-quality output at scale.

These machines can be categorized into several types, depending on the processes they support. For instance, spinning machines are used to create yarn from raw fibers, while weaving and knitting machines are used to create fabric from yarn. Dyeing and finishing machines are responsible for applying color and enhancing fabric properties.

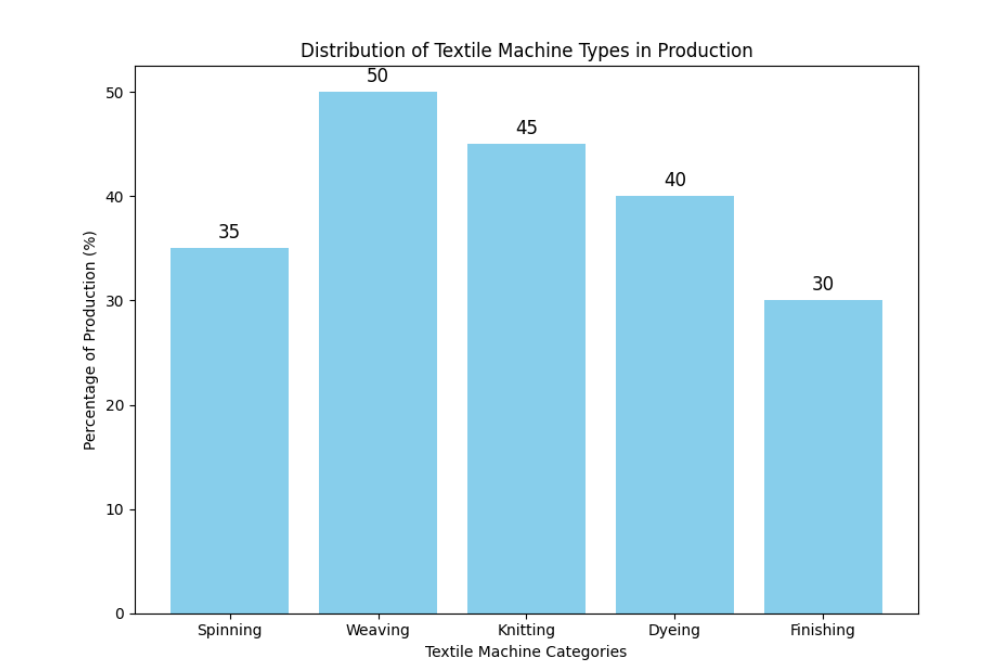

The textile industry utilizes several categories of machines, each designed to perform specific tasks. The main categories include:

● Spinning Machines: These machines convert raw fibers into yarn.

● Weaving Machines: These machines weave yarn into fabric.

● Knitting Machines: These machines knit yarn into fabrics.

● Dyeing and Printing Machines: These machines apply color and designs to fabric.

● Finishing Machines: These machines treat the fabric to improve its texture, appearance, and durability.

Each type of machine plays a crucial role in ensuring that the production process is efficient, consistent, and of high quality.

Type of Textile Machine | Function |

Spinning Machines | Convert raw fibers into yarn. |

Weaving Machines | Interlace yarns to create fabric. |

Knitting Machines | Interlock yarns to produce fabric in a continuous form. |

Dyeing Machines | Apply color to fabrics. |

Printing Machines | Apply patterns or designs to fabric. |

Finishing Machines | Enhance fabric texture, appearance, and durability. |

Spinning is the process of transforming raw fibers, such as cotton, wool, or synthetic fibers, into yarn. This is the foundational step in fabric production. The spinning process involves drawing, twisting, and winding fibers into yarn, which is then used for weaving or knitting.

Spinning machines come in different types, including ring spinning machines, open-end spinning machines, and air-jet spinning machines. These machines differ in the way they spin the yarn and the types of yarn they produce.

● Ring Spinning Machines: These are traditional spinning machines that twist and draw fibers into fine yarn.

● Open-End Spinning Machines: These machines create yarn by using a rotor that spins fibers. They are faster and more efficient than ring spinning machines.

● Air-Jet Spinning Machines: These machines use high-speed air to spin the fibers, providing high productivity and efficiency.

Advancements in spinning technology have increased the speed and efficiency of these machines, making it possible to produce large quantities of yarn quickly and with greater consistency.

Spinning is vital in determining the quality and characteristics of the fabric. The type of yarn produced affects the texture, durability, and feel of the final fabric. For example, finer yarns produce smooth, soft fabrics, while thicker yarns create stronger, more durable fabrics. By selecting the appropriate spinning technique and machinery, manufacturers can control the quality of the yarn and, in turn, the quality of the fabric.

Spinning Machine Type | Key Features | Advantages |

Ring Spinning Machine | Traditional, robust | Strong, consistent yarn |

Open-End Spinning Machine | Faster production | Lower cost, high speed |

Air-Jet Spinning Machine | High-speed operation | Energy-efficient, higher yield |

Weaving is the process of interlacing two sets of yarn (warp and weft) to form a fabric. Weaving machines are designed to perform this process at high speed and with precision. The type of loom used depends on the fabric type and the desired production speed.

Weaving machines come in several variations, such as shuttle looms, rapier looms, and air-jet looms.

● Shuttle Looms: Traditional looms that use a shuttle to carry the weft yarn across the warp yarns. These looms are slower but are ideal for producing heavy, durable fabrics.

● Rapier Looms: These looms use two rapiers to insert the weft yarn, allowing for higher speed and flexibility in fabric design.

● Air-Jet Looms: These looms use air to insert the weft yarn, allowing for faster production and higher efficiency, especially for lightweight fabrics.

Weaving machines are essential for fabric production, and their ability to operate at high speeds ensures that large volumes of fabric can be produced in a short time.

Weaving machines play a significant role in determining the quality and appearance of the fabric. The weave pattern, texture, and overall structure of the fabric depend on the type of weaving machine used. Weaving machines also allow for customization in fabric design, making them crucial for producing a wide range of textile products.

Weaving Machine Type | Main Feature | Ideal Use |

Shuttle Loom | Traditional, uses a shuttle | For intricate patterns and strong fabrics |

Rapier Loom | Fast, uses two rapiers | Suitable for a wide range of fabrics |

Air-Jet Loom | Uses air to insert weft yarn | High-speed, ideal for synthetic fabrics |

Knitting involves creating fabric by interlocking loops of yarn. Unlike weaving, which interlaces yarn in two directions, knitting uses a continuous loop of yarn to form fabric. Knitting machines are versatile and can produce a variety of fabrics, from lightweight knits to heavy sweaters.

Knitting machines offer several advantages over weaving machines, including flexibility in fabric production, faster turnaround times, and the ability to create seamless garments. There are two main types of knitting machines:

● Circular Knitting Machines: These machines knit fabric in a continuous round, which is ideal for making seamless garments.

● Flat Knitting Machines: These machines knit fabric in a flat form and are often used for making sweaters, scarves, and other garments.

Knitting machines are commonly used in the production of activewear and other stretch fabrics, as they offer superior flexibility and comfort.

Modern knitting machines help reduce waste by allowing for precise control over fabric density and texture. In addition, advances in knitting technology enable manufacturers to produce garments with minimal offcuts and fabric waste, contributing to more sustainable production practices.

Dyeing is the process of adding color to fabrics, making it one of the most important steps in textile production. Dyeing machines apply color to fabrics using various techniques and technologies. Two common types of dyeing machines are jet dyeing machines and pad dyeing machines.

● Jet Dyeing Machines: These machines use high-pressure jets to apply dye to the fabric, ensuring even color distribution and high-quality results.

● Pad Dyeing Machines: These machines pass fabric through a dye bath, ensuring that the dye is evenly absorbed by the fabric.

Printing machines are used to apply patterns and designs to fabric. Rotary screen printing and digital printing are two of the most commonly used techniques.

● Rotary Screen Printing: A traditional printing method that uses rotary screens to transfer dye onto fabric, suitable for large-scale production.

● Digital Printing: This modern method involves printing designs directly onto fabric using inkjet technology, offering high precision and reduced waste.

Recent innovations in dyeing and printing technologies focus on reducing water and chemical use. Waterless dyeing techniques and eco-friendly inks are gaining popularity in the textile industry as manufacturers prioritize sustainability. These innovations help minimize the environmental impact of textile production while maintaining high-quality results.

Finishing machines are used to treat fabrics after they have been woven or knitted. These machines improve the texture, appearance, and durability of the fabric. Common types of finishing machines include stenter machines, calendering machines, and embossing machines.

● Stenter Machines: These machines stretch and dry fabrics to achieve the desired dimensions and finish.

● Calendering Machines: These machines press fabrics under high heat and pressure to give them a smooth, shiny finish.

● Embossing Machines: These machines create textured patterns on fabric by pressing it between engraved rollers.

Finishing machines enhance the quality of fabric by ensuring that it meets the required specifications for texture, appearance, and durability. These machines play a critical role in improving the final product's look and feel.

Modern finishing machines are increasingly focused on sustainability. These machines are designed to minimize energy consumption, reduce water usage, and improve overall efficiency. By investing in eco-friendly finishing technologies, textile manufacturers can contribute to a more sustainable industry.

Automation is playing an increasingly important role in textile production. Smart textile machines are equipped with sensors and AI technology that help monitor and optimize the production process. These machines can adjust settings in real-time, reducing waste and improving efficiency.

Sustainability is a growing concern in the textile industry. Modern textile machines are being designed to reduce waste, conserve energy, and minimize environmental impact. By incorporating sustainable practices, such as waterless dyeing, energy-efficient machines, and recycling systems, textile manufacturers can meet the rising demand for eco-friendly products.

Textile machines are essential to the textile industry, ensuring efficient and consistent fabric production. From spinning to finishing, these machines help produce high-quality textiles. As the industry evolves, advancements in technology and sustainability will continue to drive the future of textile manufacturing. Companies like Jwell provide innovative solutions to meet the demands for efficient, eco-friendly production, helping manufacturers stay competitive.

A: Textile machines are specialized equipment used in the textile industry to transform raw fibers into finished products. They are involved in processes like spinning, weaving, knitting, dyeing, and finishing, contributing to efficient production and high-quality textiles.

A: Textile machines work by automating various processes in fabric production. Spinning machines twist fibers into yarn, weaving machines interlace yarns to form fabric, and dyeing machines apply colors to fabrics. These machines ensure consistency and speed in production.

A: Textile machines can be categorized into spinning, weaving, knitting, dyeing, printing, and finishing machines. Each type plays a crucial role in fabric production, with specific functions to create high-quality textiles.

A: Textile machines are crucial for manufacturers because they increase production efficiency, improve fabric quality, and reduce costs. Investing in modern [[Textile Machines]] helps stay competitive and meet market demands for high-quality, eco-friendly products.

A: The cost of textile machines varies depending on the type, size, and features. Spinning machines, weaving looms, and dyeing machines range in price, with more advanced, eco-friendly options generally costing more due to enhanced features and performance.