- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 188 Author: Site Editor Publish Time: 2025-08-20 Origin: Site

Plastic machines are essential in modern manufacturing, enabling the transformation of raw materials into products that power industries worldwide. But how many types exist, and what makes each one unique? In this post, we’ll dive into the various types of plastic machines, including molding, extrusion, and recycling machines. Each machine serves a specific purpose, playing a key role in shaping plastic into items we use daily, from containers to automotive parts. We’ll also cover the evolution of plastic molding processes and explore the latest technological innovations, highlighting their impact on efficiency, sustainability, and product quality in plastic manufacturing.

Plastic machines are essential in transforming raw plastic into useful products. They are the backbone of modern manufacturing, making everything from bottles to auto parts. Without them, many of the products we rely on every day wouldn’t exist. These machines process a variety of plastic materials, such as polyethylene, PVC, and polypropylene. These plastics are commonly used for packaging, construction, and medical devices. Plastic machinery plays a key role in producing high-tech products. For example, in the automotive industry, it helps create durable parts. In electronics, it shapes components for mobile phones. And in healthcare, it’s used to manufacture items like medical tubing. Each type of plastic machine is designed for specific processes. Whether it’s molding, extrusion, or recycling, these machines ensure that plastics are shaped efficiently and effectively for their intended use.

Plastic machines are essential in shaping and transforming raw plastic materials into usable products. These machines are designed to handle specific production processes, and each type plays a crucial role in manufacturing. Below, we will explore some of the most common types of plastic machines, starting with injection molding.

Injection molding machines are widely used in various industries for their efficiency and precision. They work by melting plastic pellets and injecting the molten plastic into a mold cavity under high pressure. Once injected, the plastic takes the shape of the mold and solidifies as it cools, forming the final product.

Automotive parts: Car components such as dashboards, bumpers, and interior trims.

Medical devices: Precision parts like syringes, IV connectors, and surgical tools.

Consumer goods: Everyday products such as toys, bottles, and household appliances.

High Efficiency: Injection molding is ideal for mass production. The process allows for quick cycle times, making it a cost-effective solution for large volumes of products.

Precision: Injection molding can produce highly detailed and complex shapes with great accuracy, ensuring that the final products meet exact specifications.

High Tooling Costs: The initial cost of creating molds for injection molding is relatively high. This makes it less economical for small production runs.

Not Ideal for Low-Volume Production: Due to the high tooling and setup costs, injection molding is not suitable for low-volume or custom production needs.

Molds for injection molding can be expensive, especially for complex shapes. However, as production volumes increase, the cost per unit decreases significantly, making it a cost-effective solution for large-scale production. The high initial investment in tooling can be recouped through the efficiency and precision of the process, especially when used for high-volume runs. Injection molding machines are versatile, capable of producing a wide range of products across industries. Despite the high initial investment, their efficiency, scalability, and ability to create intricate details make them a go-to choice for many manufacturers.

Blow molding works by inflating a heated plastic parison inside a mold. The plastic then cools and takes the shape of the mold. There are two main types of blow molding:

Extrusion Blow Molding: A tube of melted plastic is extruded and inflated in the mold.

Injection Blow Molding: Plastic is first injected into a mold, then blown to form the final product.

Bottles: Water, soft drink, and other plastic bottles.

Hollow Plastic Containers: Such as tanks and other large containers.

Ideal for mass production of hollow objects.

Efficient process, producing little material waste.

Blow molding is known for being material-efficient. The process generates very little waste, making it more environmentally friendly compared to other methods. This makes it a good choice for producing large quantities of plastic products sustainably. Blow molding machines offer a cost-effective way to produce hollow products at high volumes, making them a popular choice in many industries.

Description: Process of extrusion and the types of products created.

Common uses: Pipes, profiles, sheets, films.

Benefits of continuous production and material versatility.

Additional Context from Article: Extrusion machines are highly versatile, used to create a wide variety of products with consistent shapes.

Compression molding works by heating plastic and then pressing it between two mold halves. The plastic takes the shape of the mold as it cools and hardens.

Parts with Complex Geometries: Molding intricate designs for parts like knobs and handles.

Automotive Components: Dashboard parts, bumpers, and other car parts.

Appliance Components: Items like handles or casing for household devices.

High Precision: Ideal for producing parts with detailed shapes.

Low-Volume Production: Efficient for making smaller batches of complex parts. Compression molding is especially effective for producing thermosetting plastics. These plastics can be shaped with precision, making them ideal for intricate or specialized parts. This molding process is perfect for industries where precision and low-volume production are important, like automotive and appliance manufacturing.

In rotational molding, plastic powder is placed inside a mold, which is then heated and rotated. The rotation causes the plastic to melt and coat the inside of the mold, forming a uniform, hollow part.

Tanks: Large, durable containers for liquids.

Kayaks: Lightweight, sturdy boats.

Storage Containers: Used for bulk storage in various industries.

Material Efficiency: This process creates very little waste, making it cost-effective.

Low Waste Production: The process ensures that most of the plastic is used, minimizing leftover material.

Rotational molding allows for customization, such as adding special inserts or logos. This makes it ideal for businesses that need products tailored to specific needs or designs. This method is great for large, hollow products where durability and design flexibility are important.

Thermoforming machines shape thin plastic sheets by heating them until soft, then forming them into molds. This process is quick and efficient.

Disposable Containers: Food trays, cups, and plates.

Packaging: Blister packs, clamshells, and other protective packaging. Thermoforming is commonly used for products that require speed and flexibility in production.

Plastic welding machines are used to join plastic materials, creating a strong bond without the need for adhesives or fasteners. These machines use heat and pressure to fuse parts together.

Hot Air Welding: Uses heated air to soften and join plastic surfaces.

Ultrasonic Welding: Uses high-frequency vibrations to melt and bond plastic.

Friction Welding: Generates heat through friction to join plastic parts. Plastic welding is essential for creating durable, seamless joints in plastic products, such as automotive parts or packaging. These machines are key to producing products that require joining different plastic components, offering strong, efficient solutions.

Plastic molding is a key manufacturing process used to shape plastics into finished products. Different molding techniques are used depending on the type of product, material, and production volume.

Plastic molding involves several processes, each using specific machines. These machines apply heat and pressure to form plastic materials into shapes.

Involves injecting melted plastic into a mold cavity. It's used for high-volume production of small parts, like toys, containers, and car components.

In this process, plastic is inflated inside a mold to create hollow objects, like bottles or tanks. It’s commonly used for packaging.

Thermosetting plastic is placed in a heated mold and compressed into shape. This method is ideal for parts with complex designs or low-volume production.

Each molding technique has its own strengths, depending on the needs of the project.

Injection Molding: Best for precision and high-volume production.

Blow Molding: Ideal for hollow objects like bottles and containers.

Compression Molding: Great for intricate shapes or thermosetting materials. When deciding which method to use, consider the shape, volume, and material of the product.

Rotational molding is known for being highly efficient and environmentally friendly. It generates very little waste, making it ideal for large, hollow objects.

Extrusion molding is excellent for creating long shapes, such as pipes and profiles. It is efficient for continuous production and helps reduce material waste. Both rotational and extrusion molding are cost-effective methods for specific applications, offering low waste production and high efficiency.

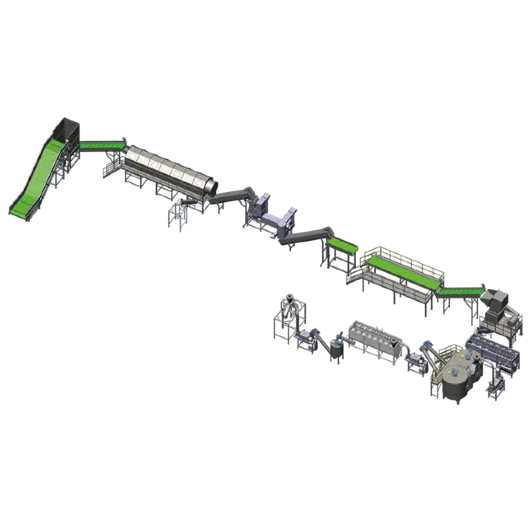

Plastic recycling is an important part of reducing waste and reusing materials. Various machines are designed to process plastic waste into reusable forms.

Recycling machines help transform plastic waste into new products by breaking it down and reshaping it. These machines play a key role in reducing plastic waste and conserving resources.

Shredders: Shredders are used to break large pieces of plastic into smaller flakes. This helps prepare the plastic for further processing, like cleaning and melting.

Pelletizers: After shredding, plastic is often melted and formed into small pellets. These pellets are easier to transport and can be used to make new products.

Extrusion Machines: Extruders melt plastic and push it through a mold to form continuous shapes, such as sheets, pipes, or profiles. This process is key in turning recycled plastic into new usable forms. These machines work together in the recycling process to create products from plastic waste, contributing to a more sustainable manufacturing cycle.

Plastic machines are crucial in transforming raw materials into products that we use every day. From molding to recycling, each type of machine plays a unique role in shaping plastics efficiently and sustainably. Injection molding, blow molding, compression molding, and other methods help create everything from consumer goods to complex automotive parts. In the recycling industry, machines like shredders, pelletizers, and extruders help break down plastic waste, making it possible to reuse materials and reduce environmental impact. By understanding how these machines work, we can appreciate their importance in the modern manufacturing process. As technology advances, plastic machines continue to evolve, becoming more efficient and environmentally friendly. The future of plastic manufacturing looks promising, with innovations aimed at sustainability and high-quality production.

A: The main types include injection molding, blow molding, compression molding, extrusion, and rotational molding machines. Each is designed for specific molding processes to create various plastic products.

A: Injection molding is used to produce high-precision parts in large quantities. Common applications include automotive parts, medical devices, and consumer goods like toys and bottles.

A: Blow molding inflates a heated plastic parison inside a mold to create hollow products like bottles, tanks, and containers.

A: Recycling machines like shredders, pelletizers, and extrusion machines break down plastic waste and form new products, making plastic reuse possible.

A: Rotational molding uses a rotating mold filled with plastic powder to produce large, hollow objects with minimal waste, ideal for items like kayaks and tanks.

A: Compression molding offers high precision and is effective for low-volume production, especially for parts with complex geometries or thermosetting plastics.