- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-04 Origin: Site

Plastic waste is a growing global issue, and many everyday items contribute to this crisis. One such item is plastic clothes hangers, which are often overlooked in recycling efforts. In this post, we’ll explore whether plastic hangers are recyclable, the challenges involved, and how Plastic Shredder Machines play a role in the process.

Plastic hangers are made from various materials, but the most common ones are Polystyrene (PS) and Polypropylene (PP). Both of these plastics are used in a wide range of consumer products, including plastic hangers, and they play a significant role in recycling challenges.

Polystyrene (PS): Polystyrene is lightweight, inexpensive, and widely used in many consumer products, including food containers, disposable cutlery, and, of course, plastic hangers. However, it has a major drawback when it comes to recycling. It is challenging to recycle due to its rigidity and tendency to break into small, difficult-to-handle pieces when shredded. PS is marked with recycling code #6, indicating that it is made from polystyrene resin. Unfortunately, this resin does not have a widely accepted recycling infrastructure, meaning it often ends up in landfills or incinerators. This material, when not properly disposed of, contributes to pollution as it breaks down into small particles called microplastics, which are harmful to wildlife and ecosystems.

Polypropylene (PP): Polypropylene, on the other hand, is more durable and flexible than polystyrene. It’s less likely to crack under pressure, making it a popular choice for products that require more strength, like containers and plastic hangers. PP is marked with recycling code #5 and is easier to recycle than polystyrene. It is more widely accepted in recycling facilities, though it still faces challenges when it comes to large-scale recycling. PP's recycling rate remains low compared to other materials, partly because it is often mixed with other resins in multi-material products like plastic hangers. However, polypropylene is still more easily processed and repurposed than polystyrene, making it a somewhat more environmentally friendly option.

In many cases, plastic hangers are made from a combination of these materials, making it difficult to separate them during the recycling process. Some hangers even contain metal hooks or other additives, further complicating the recycling process. This mixed-material composition often makes it challenging for recycling centers to determine the most appropriate processing method. As a result, many plastic hangers are either thrown away or improperly disposed of, contributing to waste buildup in landfills.

Recycling plastic hangers presents a significant challenge for many reasons. Here are some of the key factors that make the recycling of plastic hangers difficult:

Mixed Materials: Plastic hangers often contain a combination of materials, such as plastic, metal, and paint. The hooks of most plastic hangers are made from metal, which can’t be easily shredded or processed along with the plastic part. When plastic and metal are fused together, it complicates the recycling process, as recycling facilities need to separate these materials before they can be recycled properly. This is a time-consuming and costly process.

Lack of Clear Recycling Codes: Unlike plastic bottles or containers, plastic hangers often lack clear and universally accepted recycling codes. Recycling codes are numbers found inside the recycling symbols on plastic products that help recycling facilities identify the material type. Plastic hangers may not display these codes, which makes it hard for facilities to know what they’re dealing with. Without this crucial information, recycling centers might reject hangers entirely or, worse, process them incorrectly, leading to contamination of the recycling stream.

Contaminants: Many plastic hangers also carry contaminants like dirt, oil, or residue from garments. These contaminants can interfere with the recycling process and make it harder to reuse the material. For instance, the paint or lacquer on the surface of hangers can affect the ability to remold the plastic, rendering it unsuitable for reuse in the production of new products.

Due to these factors, Plastic Shredder Machines are needed to help break down plastic hangers more efficiently. These machines can process large and complex plastic waste, but even Plastic Shredders face challenges when dealing with mixed materials. The effectiveness of shredding machines is limited by the type of plastic used and its contamination level. While these machines can significantly reduce the size of the waste and make it easier to sort, they still have limitations in processing certain types of plastics.

In most cases, plastic hangers cannot be recycled through regular curbside programs. This is because most curbside collection systems are designed to handle common plastic items like bottles, containers, and bags, which are made from standardized materials that are easy to separate and recycle. Plastic hangers, on the other hand, are often made from a mixture of materials (plastic and metal) or contain coatings or finishes that make them unsuitable for standard recycling.

When plastic hangers are placed in curbside recycling bins, they are typically rejected by sorting facilities due to their complex composition. Moreover, the shape and size of plastic hangers can cause them to get caught in the machinery used to separate recyclables. In many cases, hangers with metal hooks are considered contaminated, as the metal can damage sorting equipment or affect the quality of the recycled materials.

This is where Plastic Shredder Machines come into play. These specialized machines can handle large and complex plastic items, such as hangers, and break them down into smaller, more manageable pieces. Once shredded, the plastic is easier to sort, clean, and recycle, making it suitable for further processing into new products.

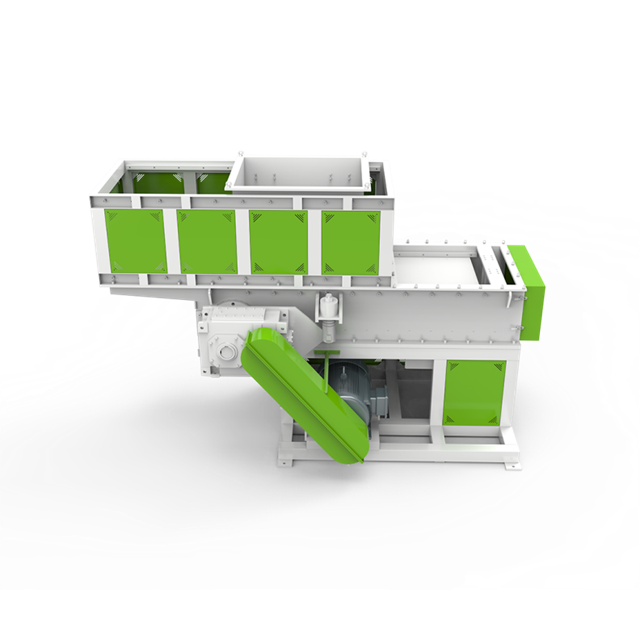

Plastic Shredder Machines are essential tools in the recycling process, designed to handle large plastic items like plastic hangers and break them down into smaller, uniform pieces. These machines play a crucial role in recycling by making plastic waste more manageable and enabling it to be processed into new products. The ability to break down and separate materials efficiently is key to ensuring that the recycled plastic can be reused rather than discarded.

The process starts when plastic hangers are fed into the shredder, typically via a conveyor system that directs them into the shredding chamber. The plastic hangers can come in a variety of shapes, sizes, and materials, including plastic mixed with metal hooks. Plastic Shredder Machines are designed to handle this complexity and reduce the size of the material.

Here’s how the process works:

Feeding the Material: Large plastic hangers are first loaded into the shredder, usually through a conveyor belt or manual feeding system. Once inside the shredder, the hangers are transported into the chamber where the shredding process begins.

Shredding:Inside the shredding chamber, the plastic hangers are subjected to the rotating blades or knives that move rapidly at high speeds. These sharp blades slice through the plastic material, breaking it into smaller pieces. The shredding blades are specifically designed to handle a range of materials, including various types of plastic with differing levels of rigidity and thickness. This ensures that no matter the type of plastic hanger, the shredder can break it down efficiently.

Sorting:After the shredding process, the smaller plastic particles are sorted based on their size, material type, and even color. Sorting is a critical step in the recycling process, as it ensures that only the appropriate materials continue through the next stages. For example, metal hooks from the hangers are separated out and can be sent for metal recycling, while plastic particles are kept together. Sorting can be done using different systems, including mechanical sorters and optical sensors, which help distinguish different types of plastic.

Recycling:Once sorted, the shredded plastic is cleaned to remove contaminants such as dirt, oils, or other residues that could affect the quality of the final recycled product. After cleaning, the plastic is then melted down and remolded into new products. This could include new plastic containers, products, or even fresh plastic hangers. The ability to repurpose plastic materials is essential for reducing the need for virgin plastic production, conserving natural resources, and minimizing waste.

Plastic Shredder Machines are indispensable in the recycling process. Without these machines, the complexity of mixed-material items like plastic hangers would make them difficult, if not impossible, to recycle. The shredding process not only makes plastic waste more manageable but also helps reduce the volume of waste sent to landfills. Recycling plastic hangers into new products reduces the environmental impact, conserving energy and raw materials, and promoting a more sustainable circular economy.

If plastic hangers are not recycled properly, they end up in landfills, where they can persist for hundreds of years. During this time, plastic hangers break down into smaller pieces, eventually contributing to microplastic pollution. These microplastics find their way into the soil, water, and oceans, where they can harm wildlife and disrupt ecosystems.

In addition to environmental concerns, improper disposal of plastic hangers also results in wasted resources. Plastic is a valuable material that can be repurposed into new products, but when it’s not properly recycled, it represents a missed opportunity to conserve resources and reduce waste. This also contributes to the growing problem of landfill overcapacity, where waste accumulates without being properly processed.

Plastic Shredder Machines help to mitigate these issues by processing plastic hangers and other complex plastic items. By breaking down the material, shredders make it possible to recycle plastic into useful products. This not only helps prevent plastics from ending up in landfills but also reduces the overall carbon footprint associated with plastic production. Recycling plastic hangers through shredding is a key step in creating a more sustainable and circular plastic economy.

There are several eco-friendly alternatives to plastic hangers that can help reduce reliance on single-use plastics. Some of the most popular options include:

Wooden Hangers: Wooden hangers are durable, stylish, and environmentally friendly. They can last for years and add an aesthetic touch to your closet. Unlike plastic hangers, they are made from natural, renewable resources, such as sustainably sourced wood.

Bamboo Hangers: Bamboo is a fast-growing and renewable resource that requires little water and no pesticides to grow. Bamboo hangers are lightweight, strong, and naturally resistant to moisture, making them a great alternative to plastic.

Recycled Plastic Hangers: If you’re still inclined to use plastic hangers, opt for ones made from recycled plastic. These hangers are made from repurposed materials, preventing new plastic from being produced and helping to reduce waste.

By choosing these alternatives, you can significantly reduce your reliance on single-use plastic hangers and help promote a more sustainable lifestyle. These alternatives are not only environmentally friendly but also often more durable, reducing the need to constantly replace hangers.

There are several ways to reduce the environmental impact of plastic hangers and minimize waste:

Donate or Reuse: If you have extra plastic hangers, donate them to thrift stores, dry cleaners, or charitable organizations. You can also reuse hangers at home for different purposes, like organizing accessories or hanging up artwork.

Upcycle: Get creative and repurpose old plastic hangers for DIY projects. You can use them to create jewelry organizers, magazine racks, or even garden trellises. Upcycling plastic hangers helps extend their lifespan and prevents them from ending up in the trash.

Businesses Can Help: For businesses, one solution is to use Plastic Shredder Machines to process unwanted plastic hangers and turn them into reusable materials. These machines break down hangers into smaller pieces that can be recycled into new products. This helps reduce waste and lowers the carbon footprint associated with plastic disposal.

Recycling plastic hangers is challenging due to their mixed materials and lack of clear recycling codes. Plastic Shredder Machines play a crucial role in breaking down hangers for proper recycling. To help reduce plastic waste, consider using eco-friendly alternatives like wooden or bamboo hangers. Responsible disposal and reuse of hangers also make a significant impact on sustainability.

A: The presence of metal hooks complicates the recycling process. Most recycling machines can't process metal alongside plastic. Plastic Shredder Machines can separate and break down the plastic, allowing for better recycling of the plastic parts.

A: Black plastic hangers are challenging to recycle because sorting machines can't detect them due to their color. However, Plastic Shredder Machines can still break down these hangers, making it easier to process and recycle the plastic.

A: Recycling plastic hangers at home is difficult due to the specialized equipment needed for shredding and sorting. Plastic Shredder Machines in recycling centers are crucial for breaking down complex plastic waste for reuse.