- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

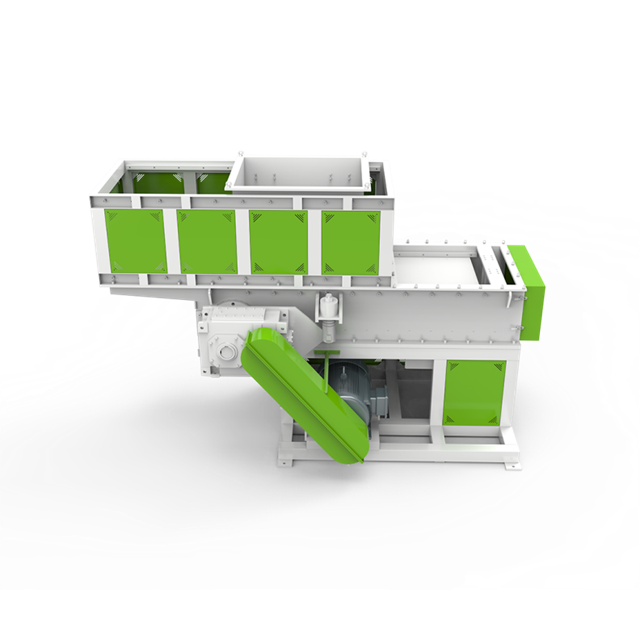

The Plastic Shredder Machine is a state - of - the - art equipment designed to handle the challenging task of reducing large - scale plastic materials into smaller, more manageable shreds. It plays a vital role in optimizing the plastic recycling and processing workflow, ensuring that plastic waste can be efficiently transformed into valuable resources.

The machine's structure is a combination of strength and innovation. The frame is fabricated from high - grade steel, providing excellent stability and resistance to deformation during heavy - duty operation. The shredding mechanism consists of multiple rows of rotating and stationary blades, which are carefully arranged to maximize the shredding efficiency.

These blades are made from wear - resistant alloy materials, capable of withstanding the harsh conditions of shredding various plastic types, including brittle plastics, flexible plastics, and composite plastics. With a modular design, the Plastic Shredder Machine can be easily customized and upgraded according to different processing requirements, making it a highly adaptable solution for diverse industrial needs.

A key feature of this Plastic Shredder Machine is its multi - stage shredding process. The plastic materials are first fed into the primary shredding chamber, where the large - sized pieces are roughly broken down by the large - diameter, low - speed blades. Then, the shredded materials are transferred to the secondary shredding chamber, where they are further refined into smaller shreds by the high - speed, fine - toothed blades. This multi - stage approach ensures a more uniform and finer shredding result, which is ideal for subsequent processing steps.

The machine also incorporates an automatic reverse function. In case of material jams or blockages, the control system will automatically reverse the rotation of the blades to clear the obstruction. This feature not only improves the safety of the operation but also reduces the downtime caused by manual intervention to unclog the machine. Additionally, the Plastic Shredder Machine is equipped with a variable - speed drive system. This allows operators to adjust the shredding speed according to the type and hardness of the plastic materials, optimizing the shredding performance and energy consumption.

Another notable feature is its environmental - friendly design. The machine is equipped with a dust - suppression system, which sprays a fine mist of water into the shredding chamber to prevent the generation of plastic dust. This helps to maintain a clean and healthy working environment, reducing the risk of dust - related health problems for operators.

Powerful shredding capability: Equipped with industrial-grade motors and durable blades, it is capable of shredding a wide range of materials, including plastics, textiles, rubber and wood.

High efficiency and high productivity: Process large amounts of materials quickly, reduce production bottlenecks and improve overall production efficiency.

Customizable shredding options: Adjust shredding speed, size and cutting strength to meet specific material requirements, providing flexibility for different applications.

Advanced safety features: Includes emergency stop button, overload protection and safety sensors to ensure safe operation and minimize risks.

Rugged and durable construction: Manufactured with heavy-duty frames and components, it is designed for stable, long-term operation in harsh industrial environments.

Easy maintenance and repair: Designed with quick access to parts, it simplifies routine maintenance and repairs and reduces downtime.

The Plastic Shredder Machine has extensive applications across multiple industries. In the plastic recycling industry, it is essential for processing post - industrial and post - consumer plastic waste. Whether it's recycling plastic films, sheets, or molded plastic products, the shredder can effectively break them down into shreds that can be further processed into recycled plastic pellets for reuse in the production of new plastic items.

In the automotive industry, the shredder is used to recycle plastic components from end - of - life vehicles, such as bumpers, dashboards, and interior trims. By shredding these plastic parts, the materials can be recovered and reused in the manufacturing of new automotive components or other plastic products.

Moreover, the Plastic Shredder Machine is widely used in the construction industry. It can shred plastic waste generated from construction sites, such as plastic pipes, insulation materials, and packaging plastics. The shredded plastic can be used as a raw material for manufacturing building materials, such as plastic - wood composites, which are widely used in decking, fencing, and other construction applications.

Model | Rotor Diameter (mm) | Drive Power (kW) | Max.pipe diameter (mm) | Output (KG/H) |

DYSSGC- 800 | Ф400 | 45 | 710 | 400-600 |

DYSSGC- 1200 | Ф400 | 75 | 1100 | 500-700 |

DYSSGC- 1400 | Ф400 | 90 | 1200 | 600-900 |

What materials can the DYSSGC Series Pipe Shredder process?

The DYSSGC Series Pipe Shredder is capable of shredding a wide range of materials, including plastics (PVC, PET, PP, PE), metals (aluminum, steel), textiles (clothing, fishing nets), and wood.

How does the DYSSGC Series Pipe Shredder ensure high efficiency?

The shredder is designed with a powerful motor and sturdy blades to process large amounts of material quickly. It reduces bottlenecks and increases production efficiency.

Can the DYSSGC Series Pipe Shredder be customized for different shredding needs?

Yes, the shredder can be customized to adjust the shredding speed, size, and cutting strength depending on the type of material to be processed.