- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 188 Author: Site Editor Publish Time: 2025-08-01 Origin: Site

Plastic waste is one of the biggest environmental challenges today. Did you know that only 9% of plastics are recycled globally?

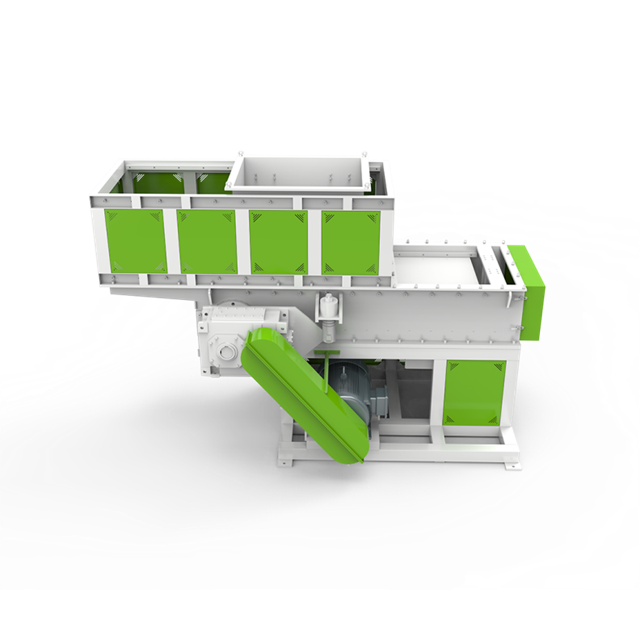

A plastic shredder machine plays a key role in tackling this issue by breaking down waste plastic into smaller, manageable pieces for recycling.

In this post, we’ll explore how plastic shredders work, their importance in sustainable recycling, and the impact they have on reducing plastic waste. You’ll learn why these machines are essential tools for a more sustainable future.

Plastic shredders work by breaking down large plastic waste into smaller, more manageable pieces. The process starts when plastic waste is fed into the shredder through a hopper or opening. This waste is then grabbed by rotating blades or cutters.

Once inside, the blades cut and shred the plastic into small pieces. These pieces vary in size, depending on the type of shredder and the material being processed. The size of the shredded material is controlled by a mesh or screen that filters out oversized pieces, ensuring the output meets the required specifications. The process is efficient, ensuring minimal energy loss while preparing the waste for recycling.

The rotor is the heart of any plastic shredder machine. It’s equipped with sharp blades that rotate and slice through plastic materials. These blades come in different configurations, such as single or multiple blades, depending on the shredder type. For instance, single-shaft shredders typically use a single rotating rotor, while multi-shaft shredders use several interlocking shafts for more thorough shredding.

Each type of rotor is designed to handle specific plastic materials. For example, a single-shaft rotor works well with softer plastics, while a multi-shaft design is ideal for tougher materials like PVC pipes or plastic films.

Screening and mesh systems play a crucial role in controlling the particle size of the shredded material. The shredded plastic passes through a screen or mesh after being cut. The size of the holes in the mesh determines how fine the output will be. This system ensures uniformity and allows operators to adjust the shredder’s output to meet the recycling needs.

Plastic shredders are equipped with several safety features to protect operators. Emergency stop buttons are installed for quick halting in case of malfunction, while protective covers shield workers from rotating blades. Some models also include automatic shut-off systems to prevent overheating or overloading, reducing the risk of accidents during operation.

Single-shaft shredders are widely used for general plastic waste, such as plastic bottles, containers, and films. They feature a single rotating shaft with sharp blades that shred the material into small, uniform pieces. This type of shredder is ideal for smaller-scale operations or materials that don’t require intensive shredding.

Two-shaft and four-shaft shredders are designed for heavier-duty tasks, handling larger, tougher plastic materials. These shredders use multiple interlocking shafts, which rotate in opposite directions, to cut through harder plastics. They are commonly used for processing items like plastic pipes, thick plastic films, and automotive parts.

Granulators are specialized machines designed to produce small plastic granules from shredded material. These are essential when smaller, more uniform particles are required. Mobile shredders, on the other hand, are mounted on trailers or trucks for on-site plastic processing. They offer the flexibility to handle large-scale plastic waste at various locations, making them ideal for industries with high plastic waste volumes or mobile recycling operations.

Plastic shredders play a key role in reducing plastic waste by breaking down large, bulky items into smaller, more manageable pieces. This makes it easier to transport and process the material, ensuring that more plastic waste can be recycled instead of ending up in landfills. They help transform plastic waste into raw material that can be used for new products, making recycling more efficient.

By reducing the volume of plastic waste, shredders help minimize the burden on landfills. This not only lowers the amount of waste being dumped but also reduces the harmful environmental effects of plastic, such as pollution in oceans and waterways. Recycling through shredding conserves natural resources by reusing plastic rather than producing new, virgin plastic, cutting down on energy consumption and reducing greenhouse gas emissions.

Recycling through plastic shredders can save money and resources in the long term. By converting plastic waste into reusable material, businesses can lower their disposal costs while creating a valuable resource that can be used in manufacturing. Furthermore, shredded plastic can be sold as raw material, creating additional revenue streams for companies that invest in shredding machines.

A circular economy focuses on minimizing waste and making the most out of existing resources. Plastic shredders fit perfectly into this model by allowing for the efficient recycling and reuse of plastic. Instead of using new, virgin plastic, businesses can recycle shredded plastic to produce new items, reducing the need for fresh raw materials. This process not only supports sustainability but also helps close the loop in plastic production and recycling.

Once plastic is shredded, it can be processed further and repurposed into new products. The shredded material can be melted, molded, and used in the production of everything from packaging to construction materials. This ensures that plastic waste doesn't just end up as waste, but is instead given a second life, contributing to a more sustainable, resource-efficient economy.

Before purchasing a shredder, it’s important to assess how much plastic you need to process. If you run a business or recycling facility, calculate your daily or monthly plastic waste volume. This will help you choose a shredder with the right capacity. Larger operations will need machines that can handle high throughput, while smaller operations might only require a shredder for lighter, less frequent tasks.

Another important factor is the size of the particles you want to achieve. Shredders allow you to adjust the size of the output, and the mesh or screen settings play a key role in this. Some processes require very fine particles, while others may only need larger, more coarse pieces. Choose a shredder that lets you control the size to match your recycling or manufacturing needs.

Different shredders are designed to handle different types of plastic. Some can easily shred soft materials like plastic films, while others are built for tougher plastics like PVC pipes or automotive parts. Make sure the shredder you choose is compatible with the plastic waste you’ll be working with. Check the manufacturer’s specifications for the types of materials the machine can handle.

Durability is key when choosing a shredder, especially if you expect it to run continuously. Look for machines made from strong materials like hardened steel and check for features that minimize wear and tear. Efficiency also matters, as a more efficient shredder can save you energy and time while processing large amounts of plastic waste. Machines designed for heavy-duty use tend to last longer and offer better long-term value.

To keep your plastic shredder in optimal condition, regular maintenance is essential. This includes lubricating moving parts, cleaning the blades, and inspecting the motor and gears for wear. Checking the machine’s performance regularly will help identify any minor issues before they turn into major problems, extending the machine’s lifespan and ensuring it operates at peak efficiency.

Even with regular maintenance, you may encounter some common issues like overheating, blade wear, or clogging. If your shredder starts overheating, check for blockages or overloaded materials that might be causing excessive friction. Blade wear is another common issue; if blades become dull, they can slow down shredding and lead to uneven cuts. Replacing or sharpening blades regularly ensures smooth operation. Clogging is typically caused by too much plastic feeding into the machine at once. Avoid overloading the shredder and ensure materials are fed gradually to avoid blockages.

Artificial intelligence (AI) is revolutionizing plastic shredding by making the process more intelligent. AI helps optimize the shredding process by automatically adjusting machine settings based on the type and volume of plastic being processed. This means the shredder can adapt to different materials in real time, ensuring more efficient operations and reducing wear on the machine. With AI, the machine can also predict potential issues before they arise, minimizing downtime and improving overall productivity.

As sustainability becomes more important, energy efficiency is a top priority in new plastic shredder models. Many modern machines are designed to consume less power while maintaining high performance. These energy-efficient models not only help reduce electricity costs but also have a smaller environmental footprint. By optimizing motor performance and incorporating power-saving technologies, these shredders are perfect for businesses looking to lower operational costs while contributing to green initiatives.

Recent advancements in blade technology are making plastic shredders more efficient at cutting through a variety of plastics. New blade materials, such as high-strength steel and titanium coatings, offer increased durability and sharper edges. These innovations allow the shredders to handle tougher materials, such as thicker plastic pipes or composite plastics, more easily. With sharper and more durable blades, shredders can process a wider range of materials in less time, improving the overall efficiency of the recycling process.

Plastic shredders are at the core of recycling facilities. They break down large plastic items into smaller, more manageable pieces that can be easily processed and recycled into new products. Whether it's bottles, containers, or plastic bags, shredders help prepare the material for further recycling steps like sorting, washing, and pelletizing. Without shredders, handling large plastic waste would be inefficient and costly.

In the plastic manufacturing industry, shredded plastic is often used as a raw material for creating new products. Shredders transform waste plastic into smaller particles, which can then be melted down and molded into new items. This process reduces the need for virgin plastic, making it more cost-effective and environmentally friendly. Manufacturers use shredded plastic in everything from packaging to consumer goods, helping close the loop in plastic production.

Waste management companies rely on plastic shredders to reduce the volume of plastic waste before it is sent to landfills or recycling plants. By shredding plastic waste, these companies can more efficiently manage the material, making it easier to transport and process. This not only reduces landfill contributions but also helps companies comply with environmental regulations by ensuring proper waste disposal and recycling.

In the food processing and packaging industries, plastic shredders are crucial for handling the vast amounts of plastic waste generated. Shredders break down packaging materials like plastic containers, films, and bottles, making them easier to recycle. By shredding plastic waste at the source, these industries can reduce the amount of waste sent to landfills, contributing to sustainability efforts and improving recycling efficiency.

Plastic shredders are also used in biomedical and laboratory settings to manage plastic waste such as medical packaging, laboratory equipment, and disposable plastics. Hospitals, clinics, and research labs generate large amounts of plastic waste that needs to be safely and efficiently processed. Shredders handle this waste, ensuring it can be disposed of or recycled according to strict regulations, preventing contamination and reducing environmental impact.

Plastic shredder machines are essential for reducing waste, saving resources, and promoting sustainability. They provide significant environmental and economic benefits by enabling more efficient recycling. As plastic waste continues to increase, the demand for shredders will rise, further driving recycling efforts.

A: Plastic shredder machines reduce the volume of plastic waste, making it easier to recycle and repurpose, helping businesses save on disposal costs and contribute to the circular economy.

A: Plastic shredders are versatile and can handle various plastics such as PET, PVC, and polypropylene, though the type of shredder used depends on the material's thickness and rigidity.

A: Consider factors like the type of plastic, shredding capacity, desired particle size, and machine durability when selecting a plastic shredder machine.

A: Regular maintenance includes cleaning the blades, lubricating moving parts, checking for wear, and replacing damaged components to ensure efficient operation.