- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Thermoplastic Elastomers (TPE) are increasingly used in everyday products, from medical devices to toys. But is TPE toxic? As it touches everything from food containers to medical devices, ensuring its safety is essential.

In this article, we will explore the safety, properties, and environmental impact of TPE, answering the critical question: is TPE toxic?

TPE, or Thermoplastic Elastomer, is a class of polymers that combine the flexibility and elasticity of rubber with the processing advantages of plastics. Unlike traditional rubbers, TPE can be molded and remolded without losing its properties, making it a highly versatile material for various applications. TPE offers the soft, rubber-like qualities that make it ideal for items requiring comfort, stretch, and flexibility.

TPE is composed of a combination of thermoplastic materials and elastomeric segments. This dual structure gives TPE its rubber-like flexibility while maintaining the ease of processing typical of plastics. Crucially, TPE is free from harmful chemicals such as phthalates, BPA, and latex, which are commonly found in other elastomers and plastics. This absence of hazardous substances plays a significant role in making TPE a safer material choice for a variety of applications.

TPE is widely used in industries such as medical, automotive, and consumer goods. In the medical field, TPE is used in medical devices like tubing, seals, and catheters. Its flexibility, resistance to sterilization, and biocompatibility make it ideal for healthcare applications. In consumer goods, TPE is commonly found in toys, sports equipment, and kitchen utensils. Its hypoallergenic nature and soft touch make it a popular choice for products that come into direct contact with the skin.

Application Area | Example Products |

Medical Devices | Medical tubing, catheters, seals |

Consumer Goods | Toys, kitchen utensils, fitness gear |

Automotive Industry | Automotive seals, interior components |

Electronics | Cable sheaths, wearables |

Children’s Products | Pacifiers, baby bottles, teething toys |

TPE is often praised for its hypoallergenic properties. Unlike latex, which can cause allergic reactions in some individuals, TPE is naturally free of proteins that trigger such reactions. This makes TPE a safer material for use in products that come into direct contact with the skin, such as medical devices, yoga mats, and children’s toys.

One of the key reasons TPE is considered non-toxic is its formulation, which avoids harmful substances like phthalates, BPA, and PVC. Phthalates, commonly used as plasticizers in PVC, have been linked to hormonal disruptions, while BPA is associated with various health concerns. TPE eliminates these risks by being free from such chemicals, making it a safer alternative in many consumer and medical applications.

TPE materials used in medical and food applications are subject to strict regulations to ensure their safety. In the United States, the Food and Drug Administration (FDA) approves TPE for use in food contact and medical applications. Additionally, TPE materials must meet international safety standards, such as those set by the European REACH regulations. This regulatory oversight ensures that TPE is safe for use in sensitive products.

Property | TPE | PVC | Latex | Silicone |

Non-toxic | Yes | No | No | Yes |

Biocompatible | Yes | No | No | Yes |

Hypoallergenic | Yes | No | No | Yes |

Recyclability | Yes | No | No | Yes |

Flexibility | High | Moderate | High | High |

Durability | High | Moderate | Low | High |

TPE is widely regarded as a biocompatible material, meaning it does not cause adverse reactions when in contact with human tissue. This makes TPE ideal for use in medical applications where direct contact with the human body is required, such as in medical tubing, seals, and catheters. The non-toxic nature of TPE also reduces the risk of complications during medical treatments.

Medical devices made from TPE can withstand various sterilization methods, including autoclaving, radiation sterilization, and chemical sterilization. TPE’s ability to maintain its integrity under these conditions ensures that it remains safe for use in healthcare environments where cleanliness and hygiene are critical. This durability makes TPE a reliable choice for both single-use and reusable medical devices.

TPE has several advantages over other materials like PVC and latex in medical applications. PVC contains harmful additives, including phthalates, while latex can cause allergic reactions in sensitive individuals. TPE, being free of these substances, provides a safer, hypoallergenic alternative for healthcare applications that require direct contact with the body.

Regulatory Standard | Description |

FDA Approval | TPE used in medical and food applications must meet FDA standards for safety |

REACH Compliance | Ensures TPE meets environmental and safety standards in the EU |

ISO 10993 | Tests TPE for biocompatibility in medical devices |

RoHS Compliance | Ensures TPE products are free from hazardous substances in electronics |

One of the major environmental benefits of TPE is its recyclability. Unlike traditional thermoset rubbers, which cannot be remolded once cured, TPE can be melted down and reshaped multiple times. This recyclability reduces waste and makes TPE a more sustainable choice compared to other materials. Furthermore, TPE production generally requires less energy and produces fewer emissions, contributing to a lower environmental footprint.

While TPE is recyclable, it is not biodegradable. This means that TPE products will not break down naturally in the environment over time. However, the recyclability of TPE mitigates some of the environmental concerns associated with its disposal, as it can be reused to create new products, reducing the need for raw materials.

TPE is often produced using more energy-efficient manufacturing methods than other materials, which contributes to its eco-friendly profile. For example, TPE production typically results in lower emissions and waste compared to the manufacturing processes of PVC and silicone. Additionally, some TPE formulations are made from renewable resources, further enhancing their sustainability.

TPE is commonly used in household products such as kitchen utensils, toys, and household cleaning tools. Its safety, flexibility, and durability make it an excellent choice for products that require regular handling. TPE is free of harmful chemicals like phthalates and BPA, ensuring that it is safe for everyday use in products that come into contact with food and skin.

TPE is a popular material for children’s products due to its non-toxic and hypoallergenic properties. From baby toys to feeding bottles, TPE offers a safe alternative to materials that may contain harmful chemicals. Its softness and flexibility make it comfortable for children to handle, while its durability ensures that the products can withstand wear and tear.

TPE provides both durability and comfort, making it ideal for products that require frequent use. Its rubber-like properties allow it to maintain its shape and performance, even under stress, while its soft touch enhances the user experience. This combination of durability and comfort makes TPE an excellent material for consumer goods that need to withstand regular wear and provide a pleasant tactile experience.

There are several misconceptions about TPE’s safety. One common myth is that TPE contains phthalates, which are harmful to human health. In reality, TPE is free from phthalates and other hazardous chemicals, making it a safer alternative to materials like PVC. Another myth is that TPE is not biocompatible, which is false. TPE has been extensively tested for biocompatibility and is considered safe for use in medical applications.

To ensure the safety of TPE products, it is essential to source materials from reputable manufacturers who follow strict safety and regulatory standards. Companies should verify that their TPE materials meet the necessary certifications and undergo rigorous testing to ensure their non-toxicity. By choosing high-quality TPE, manufacturers can offer safe products to their customers.

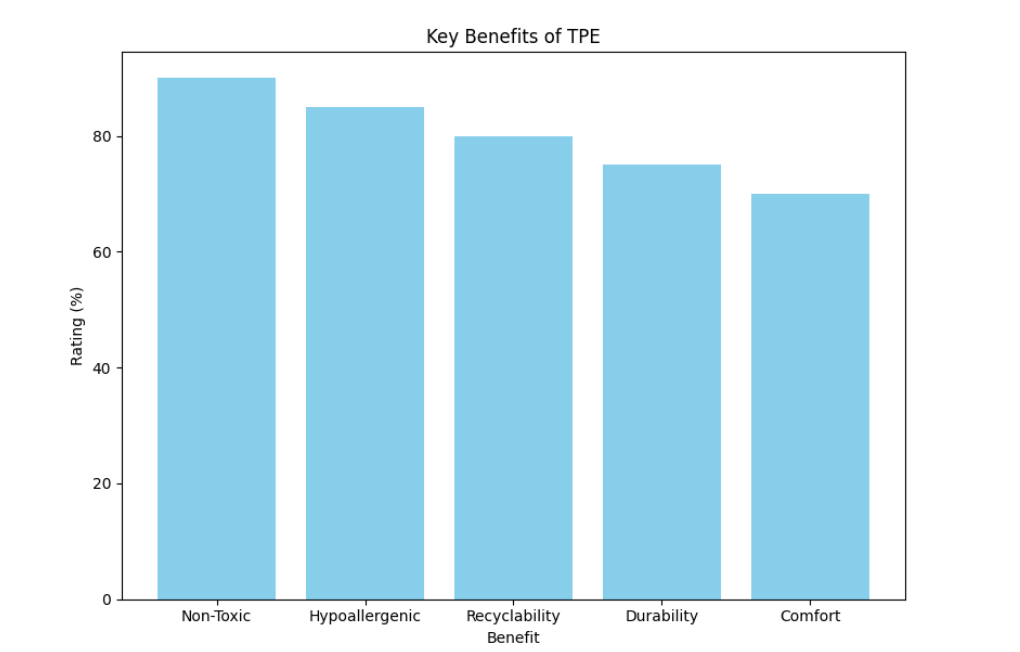

TPE is a safe, versatile, and eco-friendly material widely used in medical and consumer products. Its non-toxic nature, hypoallergenic properties, and recyclability make it ideal for direct human contact applications, such as medical devices and children's products. TPE's durability and comfort further enhance its value in everyday goods. With its sustainability and safety, TPE is a reliable choice for future product designs. Companies like Jwell provide innovative TPE solutions that meet high safety and performance standards.

A: TPE (Thermoplastic Elastomer) is a versatile material that combines the flexibility of rubber with the processability of plastic. It’s non-toxic and widely used in consumer and medical products.

A: Yes, TPE is safe for medical applications. It is biocompatible, hypoallergenic, and resistant to sterilization, making it ideal for items like medical tubing and seals.

A: No, TPE is free from harmful chemicals like phthalates, BPA, and PVC, making it a safer alternative to other materials in products like children's toys and medical devices.

A: Yes, TPE is highly recyclable, making it an eco-friendly choice for manufacturers aiming to reduce waste and improve sustainability.

A: TPE is an excellent choice for children’s products due to its non-toxic and hypoallergenic properties. It’s commonly used in toys, pacifiers, and baby products.

A: TPE is considered non-toxic because it doesn’t contain harmful substances such as phthalates or BPA, making it safe for skin contact and use in sensitive applications.