- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

PVC pipe is commonly used in construction and plumbing, but what happens when it reaches the end of its life? As environmental concerns grow, the recyclability of PVC pipe is becoming increasingly important.

In this article, we will explore whether PVC pipes can be recycled, the challenges involved, and the solutions being developed to tackle these issues.

PVC pipes are made from polyvinyl chloride, a synthetic plastic polymer. The production of PVC involves the polymerization of vinyl chloride monomer, combined with various additives like plasticizers, stabilizers, and fillers. These additives modify the physical properties of the pipe, making it more durable, flexible, and resistant to chemicals and environmental factors.

However, these additives also complicate the recycling process. Plasticizers, which are used to make PVC flexible, can leach out during recycling, contaminating the recycled material. Similarly, stabilizers used to prevent degradation under UV light can affect the quality of recycled PVC, making it less suitable for reuse in high-quality products.

PVC pipes are known for their exceptional durability and resistance to corrosion, chemicals, and high temperatures. They are commonly used in plumbing, sewage systems, agricultural irrigation, and even electrical wiring. Additionally, PVC pipes have a long lifespan and require minimal maintenance, making them cost-effective and highly reliable.

However, the very durability that makes PVC pipes ideal for infrastructure also contributes to their environmental impact when it comes to waste. Due to their robustness, PVC pipes can take hundreds of years to degrade in landfills if not properly recycled.

The presence of additives such as plasticizers, stabilizers, and fillers can hinder the recycling process of PVC pipes. These substances make PVC pipes more flexible and resistant to UV radiation, but they also make the material harder to process. During recycling, these additives can degrade the quality of the recycled PVC, which may limit its use in certain applications.

Additionally, separating PVC from other types of plastics in mixed waste can be a difficult and time-consuming task. If not properly separated, mixed plastic waste reduces the overall recycling efficiency.

PVC pipes contain chlorine, which can cause environmental issues during recycling. When PVC is heated during the recycling process, it can release chlorine gas, which is harmful to both human health and the environment. This poses a significant challenge when using conventional recycling methods like mechanical or incineration recycling.

To mitigate these risks, specialized recycling technologies must be employed to safely process PVC without releasing harmful byproducts.

PVC pipes often contain contaminants like dirt, oils, and chemicals, especially in pipes used for plumbing or sewage systems. These contaminants must be thoroughly removed before recycling, which adds to the complexity of the process. If not cleaned properly, these contaminants can affect the quality of the recycled PVC and make it unsuitable for reuse in new products.

Challenge | Description |

Additives | PVC pipes often contain plasticizers, stabilizers, and fillers that complicate recycling. |

Chlorine Content | PVC’s chlorine content can release harmful gases when melted at high temperatures. |

Contamination | Dirt, oils, and chemicals on used pipes hinder effective recycling. |

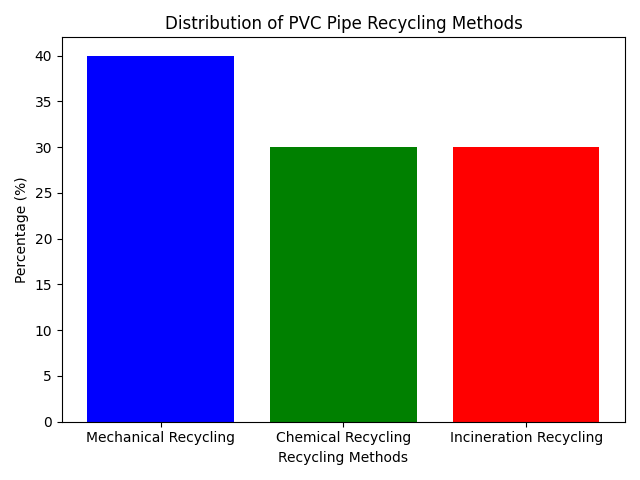

Mechanical recycling is the most common method used to recycle PVC pipes. In this process, PVC pipes are collected, cleaned, and shredded into small pieces. These pieces are then melted down and re-extruded into new products. While mechanical recycling is efficient for PVC that is clean and free of contaminants, it can be less effective when dealing with pipes that contain additives or foreign materials.

The process of mechanical recycling involves several steps, including sorting, cleaning, shredding, and remolding. High-quality recycled PVC can be used to produce new pipes or other products, although the material may not always retain the same strength and durability as the original.

Chemical recycling is a newer and more advanced technology that breaks down PVC into its chemical components. This process involves heating PVC to high temperatures and using chemicals to decompose it into simpler molecules, such as ethylene and chlorine. These chemicals can then be reused to create new PVC or used in other manufacturing processes.

Chemical recycling is particularly useful for dealing with contaminated PVC waste or PVC that is mixed with other plastics. It allows for the recovery of valuable raw materials and helps minimize waste. However, chemical recycling is more expensive than mechanical recycling and is still in the development phase.

When recycling is not feasible due to contamination or other factors, PVC pipes can be incinerated. Incineration recycling involves burning PVC waste at high temperatures to recover energy or reduce waste volume. However, this method poses environmental risks, as burning PVC can release toxic gases such as dioxins and chlorine. Therefore, incineration is generally considered a last resort for PVC disposal and must be carefully controlled to prevent harmful emissions.

Method | Description | Advantages | Challenges |

Mechanical Recycling | Shredding, cleaning, and re-extruding PVC into new products. | Easier for clean PVC, lower environmental impact. | Contaminants and additives affect quality. |

Chemical Recycling | Breaking down PVC into original components like ethylene and chlorine. | Can handle more contaminated PVC materials. | High cost, requires advanced technology. |

Incineration Recycling | Burning PVC to recover energy. | Provides energy recovery. | Releases toxic gases and harmful byproducts. |

When PVC pipes cannot be recycled due to contamination, degradation, or the complexity of the recycling process, they may end up in landfills or be incinerated for energy recovery. However, improper disposal of PVC can lead to long-term environmental damage. PVC is a non-biodegradable material, and when it breaks down in landfills, it can leach toxic chemicals into the soil and water.

To prevent this, it is essential to improve PVC recycling infrastructure and adopt more efficient recycling technologies. Additionally, incineration must be carefully managed to minimize harmful emissions.

Method | Recycling | Disposal |

Recycling | Reduces waste, saves energy, and prevents environmental harm. | PVC can be reprocessed into new products, reducing landfill waste. |

Incineration | Provides energy recovery but releases toxic substances. | Releases harmful chemicals like dioxins into the atmosphere. |

Landfill | Not an ideal method as PVC is not biodegradable. | Contributes to long-term environmental harm. |

In Europe, VinylPlus® is a key initiative focused on improving the sustainability of PVC products. VinylPlus® is committed to recycling at least 900,000 tonnes of PVC waste per year by 2025 and aims to recycle 1 million tonnes by 2030. This initiative has already made significant progress, with over 737,000 tonnes of PVC waste recycled in 2023.

The success of VinylPlus® demonstrates that large-scale PVC recycling is possible, and it highlights the importance of industry collaboration in advancing recycling efforts.

Many countries and municipalities are implementing local PVC pipe recycling programs. These initiatives often involve collecting PVC waste from construction sites or households and sending it to specialized recycling facilities. However, the effectiveness of these programs varies, and more investment in infrastructure and public awareness is needed to increase recycling rates.

The future of PVC pipe recycling looks promising, with innovations in both mechanical and chemical recycling technologies. Optical sorting technologies are being developed to improve the separation of PVC from other materials, which will enhance recycling efficiency. Additionally, advances in chemical recycling may allow for better handling of mixed or contaminated PVC waste.

One promising trend is the development of more sustainable PVC materials. Manufacturers are exploring ways to reduce harmful additives in PVC pipes, making them easier to recycle and less damaging to the environment. Eco-friendly design practices, such as creating PVC pipes that can be more easily disassembled and reused, are also gaining traction in the industry.

PVC pipes face recycling challenges due to additives and contaminants, but advances in recycling technology are improving their recyclability. As awareness of environmental issues grows, sustainable practices in PVC pipe recycling are increasingly in demand. With better recycling technologies and infrastructure, PVC recycling can contribute to a circular economy. Companies like Jwell are helping lead the way with innovative solutions to enhance the recycling of PVC pipes, offering eco-friendly products that reduce environmental impact.

A: Yes, PVC pipes can be recycled, but the process is more challenging due to additives and contaminants present in the material.

A: The presence of additives like plasticizers, stabilizers, and fillers complicates the recycling process, affecting the quality of recycled PVC pipe material.

A: PVC pipes are typically recycled through mechanical and chemical processes. Mechanical recycling involves shredding and re-extruding, while chemical recycling breaks them down into original components.

A: Non-recyclable PVC pipe may be sent to landfills or incinerated, which can cause environmental harm if not handled properly.

A: Yes, initiatives like VinylPlus® in Europe aim to improve PVC recycling rates, focusing on sustainable practices and better recycling technologies.