- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-12-30 Origin: Site

Sheet extruder machines are essential in producing high-quality plastic sheets used across various industries like packaging, automotive, and construction. But how exactly do these machines work to ensure consistent results?

In this article, we will explore the working principle of sheet extruder machines, highlighting the key components, applications, and advantages. You'll learn how these machines help streamline production and improve efficiency across industries.

A sheet extruder machine is a type of manufacturing equipment used to convert plastic pellets or granules into continuous sheets. The process begins with plastic material being melted and forced through a specially designed die to create a uniform sheet of plastic. This process ensures that the produced sheets have consistent thickness, smooth surfaces, and high durability.

The extrusion process involves several stages. First, raw plastic material is fed into the extruder, where it is heated and melted. This molten plastic is then pushed through a die, typically a T-shaped or coat-hanger design, that shapes the material into the desired sheet form. The cooling system quickly solidifies the plastic, and the sheet is then cut to length for packaging or further processing.

The hopper is the first part of the sheet extruder machine where the plastic material is loaded. It functions as a container that stores the raw plastic, usually in pellet form. This material is fed into the extruder in a controlled manner, ensuring that the flow is consistent and the plastic melts uniformly. In some cases, additives like colorants or stabilizers are added at this stage to modify the properties of the final sheet.

The screw is the heart of the extruder machine. It rotates and moves the plastic material through the extruder barrel. The screw generates the necessary heat and pressure through friction, helping to melt the plastic and ensure it flows smoothly. The screw design is critical for maintaining the right balance between melting and pushing the material, and it ensures that the plastic is fully homogenized before being shaped.

The die head is where the molten plastic is shaped into a flat sheet. It is typically a T-shaped or coat-hanger die, which ensures that the material flows evenly and maintains consistent thickness across the sheet. The die's design is crucial because it directly impacts the surface quality and thickness uniformity of the final product.

After the molten plastic exits the die, it enters a cooling system, usually involving calender rolls. These rollers cool and flatten the sheet, controlling its thickness and ensuring a smooth surface. The speed and temperature of the rollers play a significant role in the final properties of the sheet, including texture and gloss. Calendering is essential for achieving uniform thickness and high-quality surface finishes.

Once the sheet has cooled and been formed, it is cut into the desired length using a precision cutting system. This system is designed to handle sheets of various thicknesses and lengths, ensuring accuracy and minimizing material waste. For thin sheets, shear cutting is often used, while thicker sheets may require saws for cutting.

Component | Function |

Hopper & Feeding System | Feeds raw materials into the extruder for processing. |

Extruder Screw | Melts and compresses the material, ensuring even plasticization. |

Die Head | Shapes the molten material into a continuous sheet. |

Cooling System & Calender Rolls | Solidifies the sheet and controls thickness and texture. |

Cutting System | Cuts the extruded sheet to the desired length and ensures precision. |

The working process of a sheet extruder machine can be broken down into several key steps:

1. Feeding: Raw plastic is loaded into the hopper, where it is gravity-fed into the extruder barrel.

2. Melting & Plasticizing: The extruder screw rotates, generating heat and friction that melts the plastic, preparing it for shaping.

3. Shaping: The molten plastic passes through the die head, where it is shaped into a flat sheet.

4. Cooling & Calendering: The sheet is cooled using rollers, which also regulate the thickness and surface texture.

5. Cutting: The cooled sheet is cut to the required length, ready for further processing or packaging.

In sheet extrusion, the continuous process is more common. The continuous process allows for high-volume production, as sheets are produced nonstop, moving through the extruder at a steady pace. This process is highly efficient and ideal for large-scale manufacturing. In contrast, batch extrusion is used for specialized products or when production runs are smaller. It is less common in sheet production but still employed for specific materials or custom shapes.

Sheet extruder machines are extensively used in the packaging industry. They are employed to produce sheets that are later thermoformed into various packaging products such as trays, containers, and blister packs. These sheets are highly versatile, allowing manufacturers to create lightweight, durable packaging materials that meet food safety standards and other regulatory requirements.

In the construction industry, sheet extruders are used to produce durable, weather-resistant materials. Extruded plastic sheets are used in applications such as cladding, flooring, and protective barriers. The strength and flexibility of these sheets make them ideal for construction projects, offering both aesthetic and functional benefits.

The automotive industry benefits from sheet extruders by producing interior and exterior parts for vehicles. For example, plastic sheets are used for dashboard components, door panels, and trim. The ability to create strong, lightweight materials with consistent surface finishes makes extruded sheets highly valuable in this sector.

Sheet extruders are also used in the medical device industry to produce plastic sheets for casings and other components. These sheets are often used for medical packaging, IV bags, and surgical instrument covers. The ability to manufacture precise, clean sheets is essential in the medical field, where product quality and safety are paramount.

The single-screw extruder is the most widely used machine for sheet production due to its simplicity and cost-effectiveness. This type of extruder is ideal for producing uniform sheets with consistent quality, especially when the application does not require complex material processing. Its straightforward design makes it reliable, efficient, and easy to maintain, making it a go-to choice for standard extrusion needs.

The twin-screw extruder is designed for more intricate extrusion tasks. It is particularly effective for processing materials that require intensive mixing or for producing multi-layer sheets. The intermeshing screws generate higher shear forces, which help achieve superior material homogenization. This results in better control over material properties, such as improved strength, consistency, and the ability to work with challenging material combinations. Twin-screw extruders are commonly used in industries that demand advanced processing capabilities.

Co-extrusion lines are advanced systems that enable the production of multi-layer sheets. By combining different materials during the extrusion process, co-extrusion creates sheets with customized properties, such as enhanced durability, strength, or barrier capabilities. This technology is particularly beneficial in applications such as packaging, where specific properties like moisture resistance or UV protection are needed. Co-extrusion allows manufacturers to create highly specialized products that meet specific functional or aesthetic requirements.

Type of Extruder | Key Features | Ideal for |

Single-Screw Extruder | Simple design, cost-effective | Standard sheet production |

Twin-Screw Extruder | Better mixing, suitable for complex materials | Multi-material blends, improved mixing |

Co-extrusion Lines | Multi-layer extrusion for enhanced properties | Special applications requiring multi-layer products |

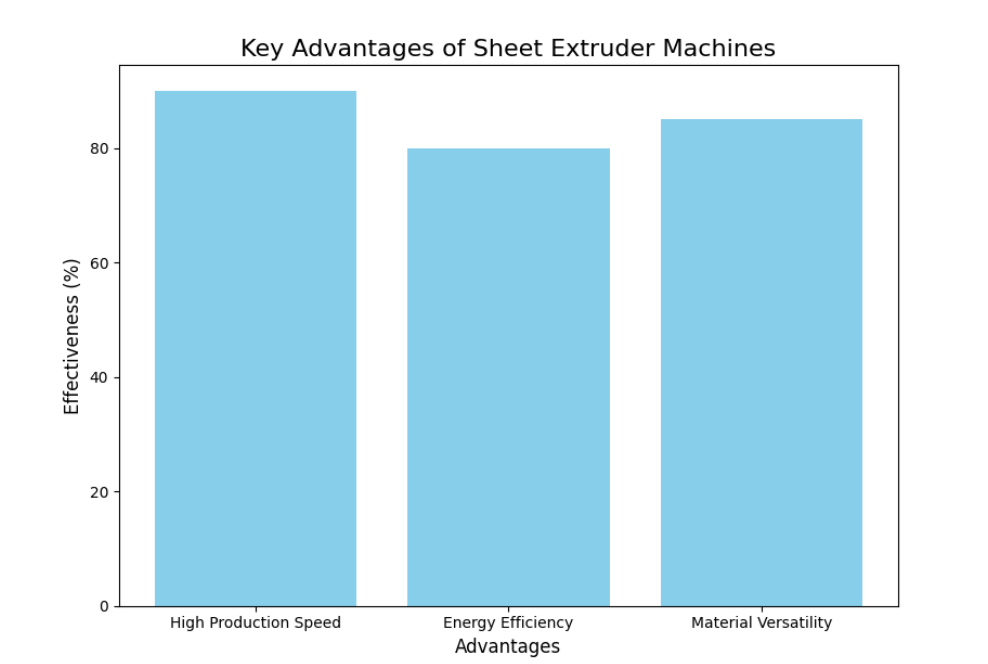

One of the most significant advantages of sheet extruder machines is their ability to produce large quantities of sheets at a high speed. This continuous production process minimizes downtime, allowing for faster turnaround times and greater output. The high production speed not only helps reduce overall manufacturing costs but also increases efficiency, making it ideal for industries that require consistent and high-volume sheet production, such as packaging, construction, and automotive manufacturing.

Modern sheet extruders are designed with energy efficiency in mind, helping to lower operational costs and reduce the environmental impact. These machines incorporate advanced heating and cooling systems that regulate energy consumption, ensuring optimal performance while using less energy. By optimizing energy usage, manufacturers can significantly reduce electricity costs, contributing to long-term cost savings and enhanced sustainability in the production process.

Another key benefit of sheet extruders is their ability to process a wide variety of materials, including popular plastics like PE, PVC, PP, and PET. This versatility enables manufacturers to produce sheets for a broad range of applications, from packaging and construction to medical devices and automotive parts. The adaptability of sheet extruders allows manufacturers to meet diverse market demands and create custom products with specific material properties, making them an essential tool for businesses in various industries.

The integration of automation and IoT technologies is revolutionizing sheet extrusion. Modern extruders are now equipped with sensors and PLC systems that allow for real-time monitoring and optimization of the production process. This automation reduces human error, improves consistency, and increases efficiency.

As the demand for environmentally friendly products rises, the sheet extrusion industry is focusing on sustainability. Innovations such as the use of biodegradable plastics, reduced energy consumption, and waste reduction are becoming more common in modern sheet extruder machines.

Sheet extruder machines play a vital role in producing high-quality plastic sheets for industries such as packaging, automotive, and construction. By understanding their working principles and components, manufacturers can optimize production and improve product quality. Continuous advancements in technology will further enhance efficiency and sustainability in sheet extrusion.

Choosing the right extruder machine, like those offered by Jwell, ensures high-quality output, reduces waste, and boosts production capabilities, making it a valuable investment for modern manufacturing.

A: A sheet extruder machine is a device used to melt plastic and force it through a die to produce continuous sheets for various applications like packaging and construction.

A: An extruder machine melts raw plastic pellets and uses a rotating screw to push the material through a die, shaping it into uniform sheets that are cooled and cut.

A: Key components include the hopper, extruder screw, die head, cooling system, and cutting system, each playing a critical role in producing high-quality plastic sheets.

A: Single-screw, twin-screw, and co-extrusion machines are commonly used, each offering specific advantages in terms of efficiency and material processing.

A: Selecting the right extruder machine ensures consistent product quality, reduces waste, and optimizes production efficiency, making it crucial for long-term manufacturing success.