- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2026-01-22 Origin: Site

Have you ever wondered how plastic products are made? Single screw extruders play a crucial role in this process. These machines melt and shape raw materials into various forms. In this post, we'll explore what single screw extruders are used for and why they are essential in manufacturing.

Single screw extruders are essential machines in the manufacturing process, consisting of several key components. Understanding these parts helps us grasp how they function effectively.

1. Screw: The heart of the extruder, the screw continuously rotates to push the resin forward. It has a specific design to ensure proper mixing and flow of materials. The geometry of the screw influences melting, pressure buildup, and mixing efficiency.

2. Barrel: This is the heated chamber where the raw materials are melted. The barrel's temperature is carefully controlled to achieve the right melting point for the specific material being processed. It plays a crucial role in maintaining the quality of the extruded product.

3. Drive Mechanism: This component powers the screw's rotation. It typically includes a motor, reducer, and bearing system. A stable screw speed is vital for consistent product quality, as it affects the throughput and overall efficiency.

4. Resin Feed System: This system feeds the solid resin pellets or powders into the extruder. It ensures a continuous supply of material, which is essential for maintaining production rates.

5. Control Systems: These systems manage the temperature, pressure, and speed of the extruder. They help optimize the extrusion process by allowing operators to monitor and adjust conditions in real-time.

The operation of a single screw extruder involves a well-coordinated interaction between these components. When solid resin enters the barrel, the screw begins to rotate, pushing the material forward. As the resin moves through the heated barrel, it gradually melts into a homogeneous molten state.

This process can be illustrated in the following table:

Step | Description |

1 | Feeding: Solid resin is introduced into the feed system. |

2 | Melting: The screw rotates, moving the resin through the heated barrel. |

3 | Mixing: The design of the screw ensures thorough mixing of the material. |

4 | Extrusion: The molten resin is forced through a die to create the desired shape. |

The combination of temperature control, screw design, and feed rate ensures that the extruded product meets quality standards.

A barrier screw is a specialized design that enhances the melting process. Unlike traditional screws, barrier screws have additional flights in the transition zone. This design separates solid and molten plastic into different channels, improving melting efficiency.

As solid pellets move forward, they are sheared against the barrel wall, leading to better heat transfer and faster melting. The molten material then flows into a separate channel, allowing for a more homogeneous melt. This results in higher-quality products with fewer defects.

In summary, the key components of single screw extruders work in harmony to create a smooth, efficient extrusion process. Understanding these parts and their functions is crucial for optimizing production and ensuring product quality.

Single screw extruders are versatile machines used across various industries. Their ability to efficiently process different materials makes them essential in modern manufacturing. Let’s explore how different sectors utilize single screw extruders.

Single screw extruders play a vital role in the plastic packaging industry. They are used to produce a wide range of products, including:

● Films: Thin sheets used for wrapping and packaging.

● Sheets: Rigid plastic sheets for containers and displays.

● Containers: Various types of packaging for food and consumer goods.

Quality and safety are paramount in this sector. Extruded products must meet strict standards to ensure they are safe for food contact and other applications. Major packaging firms, such as Amcor and Sealed Air, rely on single screw extruders to produce millions of items annually, ensuring consistency and quality.

Product Type | Application |

Films | Food and retail packaging |

Sheets | Signage and displays |

Containers | Bottles and boxes |

In the automotive industry, single screw extruders are crucial for producing various components. Common parts made include:

● Seals: Essential for preventing leaks.

● Gaskets: Used in engines and assemblies.

● Trim Profiles: Decorative and functional parts for vehicles.

Precision and material consistency are critical in this field. Automakers demand high-quality components to ensure safety and performance. Automation enhances production efficiency, allowing manufacturers to increase throughput and reduce defects. Companies like Ford and General Motors utilize these technologies to maintain high standards.

Single screw extruders are also widely used in producing construction materials. They manufacture:

● Pipes: Essential for plumbing and drainage.

● Window Profiles: Frames for energy-efficient windows.

● Insulation Materials: Used for thermal protection in buildings.

The use of recycled plastics is a growing trend in this sector, driven by sustainability goals. Customization capabilities allow manufacturers to create specific profiles and sizes, significantly impacting lead times and costs. For instance, firms like PPR Pipe and Rehau leverage single screw extruders to meet diverse customer needs.

In the medical field, single screw extruders are vital for producing components like:

● Tubing: Used in various medical applications.

● Catheters: Essential for patient care.

Compliance with health and safety standards is crucial. Products must meet stringent regulations to ensure patient safety. As materials and process controls improve, adoption of single screw extruders in healthcare is increasing. Companies like Medtronic and Becton Dickinson utilize these machines to enhance production efficiency.

Single screw extruders also play a significant role in the electronics industry. They are used to create:

● Lightweight Casings: Protect devices while minimizing weight.

● Internal Components: Parts that support device functionality.

The design intricacies of electronic devices require precise manufacturing processes. High-volume production is essential to meet consumer demand for sleek, portable gadgets. As technology evolves, manufacturers are increasingly relying on advanced extrusion techniques to keep up with market trends.

Industry | Key Products |

Plastic Packaging | Films, sheets, containers |

Automotive | Seals, gaskets, trim profiles |

Construction | Pipes, window profiles, insulation |

Medical | Tubing, catheters |

Consumer Electronics | Casings, internal components |

Single screw extruders are indispensable across these industries, driving efficiency and innovation. Their ability to produce high-quality products while adapting to various materials makes them a cornerstone of modern manufacturing.

Single screw extruders offer numerous benefits that make them a popular choice in various manufacturing processes. Their design and functionality contribute to their effectiveness in producing high-quality products efficiently.

1. Simplicity and Efficiency

2. One of the primary advantages of single screw extruders is their straightforward design. This simplicity leads to efficient operation, allowing for consistent production rates. The single screw mechanism requires less complexity compared to twin-screw systems, making it easier to operate and maintain. As a result, manufacturers can achieve high output with minimal downtime.Versatility in Processing Different Materials

3. Single screw extruders are incredibly versatile. They can process a wide range of materials, including various types of plastics, composites, and even some food products. This flexibility allows manufacturers to adapt to changing market demands and experiment with new materials. For example, they can easily switch from processing polyethylene to polypropylene without significant modifications.Cost-Effectiveness and Low Maintenance

The design of single screw extruders contributes to lower operational costs. Their simpler construction means fewer parts that could wear out or require replacement. This translates to lower maintenance expenses over time. Additionally, the energy efficiency of single screw extruders helps reduce overall production costs, making them an attractive option for businesses looking to maximize profitability.

Feature | Advantage |

Simplicity | Easier to operate and maintain |

Versatility | Can process various materials |

Cost-Effectiveness | Lower operational and maintenance costs |

Energy Efficiency | Reduces overall production costs |

4. Environmental Benefits

In today’s eco-conscious world, sustainability is key. Single screw extruders contribute to environmental benefits by reducing waste during the manufacturing process. Their efficient melting and processing capabilities minimize material loss. Furthermore, many manufacturers are now using recycled materials in their production, which aligns with sustainability goals. This not only conserves resources but also helps companies meet regulatory standards for environmental impact.For instance, companies like BASF and Dow are increasingly incorporating recycled plastics into their extrusion processes, showcasing the environmental advantages of single screw extruders.

By leveraging these benefits, businesses can enhance their production processes while also contributing to a more sustainable future. The combination of simplicity, versatility, cost-effectiveness, and environmental responsibility makes single screw extruders an essential tool in modern manufacturing.

The field of single screw extruders has seen significant advancements in recent years. These innovations enhance performance, efficiency, and sustainability, making these machines even more valuable in manufacturing processes.

1. Improved Screw Designs and Automation

2. Modern single screw extruders now feature advanced screw designs that optimize material flow and melting efficiency. These new designs often include special geometries, such as barrier screws, which enhance mixing and reduce energy consumption. Automation has also transformed the industry, enabling manufacturers to achieve precise control over the extrusion process. Automated systems can adjust parameters in real-time, ensuring consistent product quality and reducing waste.Real-Time Monitoring and Its Impact on Performance

Real-time monitoring technologies have become integral to modern single screw extruders. By utilizing sensors and data analytics, manufacturers can track critical parameters like temperature, pressure, and screw speed. This data allows for immediate adjustments, leading to improved performance and reduced downtime. For example, companies can identify potential issues before they escalate, ensuring a smoother production process.

Monitoring Parameter | Impact on Performance |

Temperature | Ensures optimal melting and processing |

Pressure | Maintains consistent extrusion quality |

Screw Speed | Enhances throughput and reduces defects |

3. Environmental Considerations and Sustainability

4. As sustainability becomes increasingly important, innovations in single screw extruder technology focus on reducing environmental impact. Many manufacturers are now incorporating recycled materials into their processes, which aligns with global sustainability goals. Additionally, energy-efficient designs help minimize power consumption, further contributing to a greener manufacturing process.Advanced Features

New features in single screw extruders enhance their capabilities. For instance, secondary flights on screws improve material mixing and melting efficiency, allowing for better quality products. Automatic gravimetric feeders ensure precise material input, which is crucial for maintaining consistency in production. These innovations not only streamline operations but also help manufacturers adapt to varying material properties.

Advanced Feature | Benefit |

Secondary Flights | Enhanced mixing and melting efficiency |

Automatic Gravimetric Feeders | Precise material input for consistency |

These advancements in single screw extruder technology are reshaping the manufacturing landscape. By integrating improved designs, automation, and sustainability practices, manufacturers can enhance their production processes and meet the demands of a rapidly evolving market.

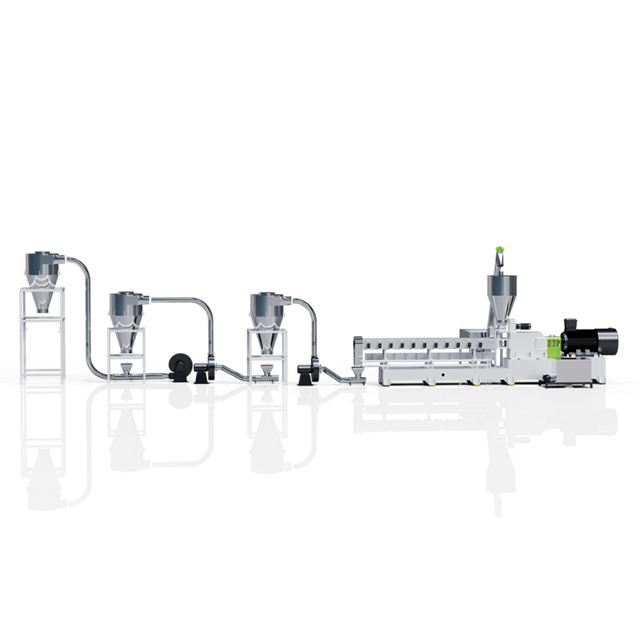

Single screw extruders are not standalone machines; they are integral components of larger manufacturing systems. Their integration with upstream and downstream processes enhances overall efficiency and productivity. Let’s explore how these machines fit into manufacturing workflows and the automation features that are transforming their operation.

In a typical manufacturing setup, single screw extruders interact closely with various upstream and downstream systems.

● Upstream Systems: These include material handling and feeding systems, where raw materials are prepared and delivered to the extruder. Efficient upstream integration ensures a steady supply of materials, which is crucial for maintaining consistent production rates. For instance, automated feeders can precisely deliver the right amount of resin to the extruder, minimizing waste and optimizing material usage.

● Downstream Systems: After the extrusion process, products often require additional processing, such as cutting, cooling, or packaging. Integrating downstream equipment, like cooling tanks or automated cutting machines, allows for seamless transitions from one stage to the next. This integration reduces handling time and enhances product quality by ensuring that the extruded materials maintain their properties throughout processing.

Integration Aspect | Description |

Upstream Systems | Material handling and feeding systems |

Downstream Systems | Cooling, cutting, and packaging equipment |

Automation is revolutionizing the way single screw extruders operate. Various advanced features are now commonly available, enhancing efficiency and reliability.

1. Predictive Maintenance: This feature uses data analytics to monitor the condition of the extruder. By analyzing performance metrics, manufacturers can predict potential failures before they occur. This proactive approach minimizes unexpected downtime and prolongs the lifespan of the equipment.

2. IoT Integration: The Internet of Things (IoT) allows for real-time data collection and monitoring. By connecting extruders to a centralized system, manufacturers can track performance metrics, optimize settings, and make informed decisions based on live data. This connectivity enhances operational visibility and allows for quicker responses to any issues.

Automation Feature | Benefits |

Predictive Maintenance | Reduces downtime and maintenance costs |

IoT Integration | Enhances operational visibility |

The integration of automation features in single screw extruders leads to numerous benefits. Enhanced efficiency is one of the most significant advantages. By automating routine tasks and monitoring performance, manufacturers can streamline operations, reduce manual intervention, and improve overall productivity.

Moreover, automation helps in minimizing downtime. Predictive maintenance ensures that any potential issues are addressed before they escalate, allowing for uninterrupted production. This not only saves time but also reduces costs associated with equipment failure and repairs.

Incorporating single screw extruders into larger automated manufacturing processes is becoming increasingly common. By leveraging integration and automation, manufacturers can achieve higher efficiency, lower operational costs, and improved product quality.

Single screw extruders play a crucial role in multiple industries, from packaging to automotive manufacturing. Their efficiency and versatility make them essential for producing high-quality products. Innovations in automation and integration enhance their performance and sustainability.

For those interested in single screw extruder technology, exploring its applications can provide valuable insights. Companies like Jwell offer advanced solutions that deliver exceptional value. Their products are designed to meet diverse manufacturing needs while ensuring optimal efficiency and quality.

A: A single screw extruder is a machine used to process materials, primarily plastics, by melting and shaping them through a single rotating screw.

A: It works by feeding raw materials into a heated barrel where the screw rotates, mixing and melting the materials to form a continuous product.

A: Single screw extruders are known for their simplicity, cost-effectiveness, and versatility in processing various materials.

A: They are popular due to their efficiency in producing consistent quality products and their ability to integrate with other manufacturing processes.

A: Factors include the machine's size, features, and the materials it can process, as well as automation capabilities.

A: Common troubleshooting steps include checking temperature settings, ensuring proper material feed, and inspecting for blockages in the screw or barrel.