- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-17 Origin: Site

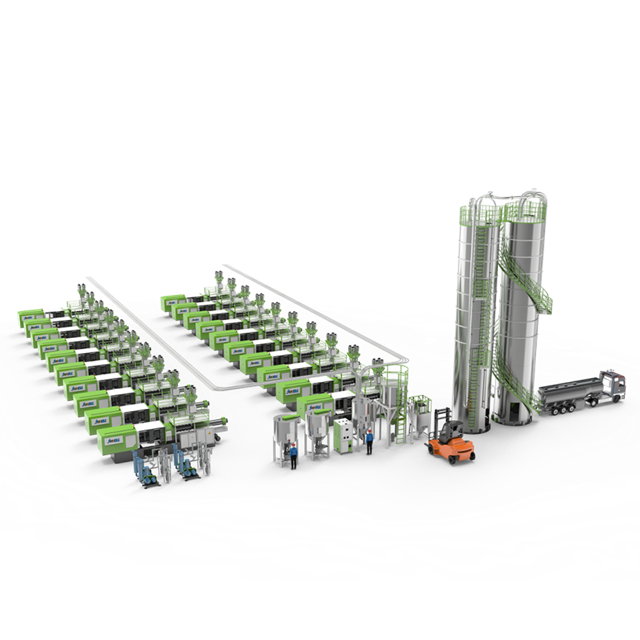

In the fast-paced world of plastic manufacturing, efficiency is key. As the industry evolves, technological advancements play a crucial role in staying competitive. One such innovation is the central feeding system, revolutionizing how raw materials are handled. In this post, you'll learn how the Wensui central feeding system enhances production efficiency, reduces labor, and ensures consistent material flow in plastic machinery.

A central feeding system in plastic machinery automates the delivery of raw materials to multiple processing machines, such as injection molding or extrusion machines. Its main purpose is to ensure a steady, controlled supply of plastic resins and additives, improving production efficiency and reducing manual labor.

At its core, the central feeding system manages the storage, drying, conveying, and distribution of raw materials from a centralized location to each machine on the factory floor. This setup replaces the traditional method where materials are manually loaded beside each machine. Instead, it uses vacuum or pressure conveying to transport materials through pipelines, enabling continuous feeding without interruption. The system also supports material preparation tasks like drying and blending, essential for high-quality molding.

● Automation: The system operates automatically, controlled by a central computer or PLC, allowing 24/7 operation with minimal human intervention.

● Consistency: It maintains consistent material flow and quality by precisely measuring, drying, and mixing materials before delivery.

● Efficiency: By centralizing material handling, it reduces labor costs and operational downtime.

● Cleanliness: Centralized storage and conveying reduce contamination risks, creating a cleaner production environment.

● Space Saving: Eliminates the need for bulky material handling equipment around each machine, freeing up valuable floor space.

The central feeding system plays a vital role in factory automation. It integrates with other auxiliary equipment like dryers, dehumidifiers, and blenders to prepare materials optimally before molding. The system's centralized control allows operators to monitor and adjust feeding parameters remotely, ensuring smooth production and quick response to any issues. This automation enhances overall productivity, reduces errors, and supports uninterrupted manufacturing cycles.

By streamlining raw material handling, the central feeding system enables plastic manufacturers to meet high production demands while maintaining product quality and reducing operational costs.

The central feeding system operates as a fully integrated network designed to automate raw material delivery to multiple injection molding machines. Its workflow revolves around three core processes: central control console operations, material transportation, and seamless integration with molding machines.

At the heart of the system lies the central control console, often powered by an industrial computer or PLC. This console manages every function, including starting and stopping material flow, monitoring system status, and triggering alarms for any irregularities. Operators use a touchscreen interface to adjust parameters like feeding schedules, drying times, and material types. Real-time data helps them optimize production and quickly address issues such as pipe blockages or low material levels. The console also coordinates auxiliary equipment like dehumidifiers and dust collectors to maintain material quality.

Raw materials begin their journey stored in centralized silos or bins. From there, vacuum or pressure conveying systems transport the plastic resins through stainless steel pipelines. Vacuum pumps create suction that pulls materials from storage to drying hoppers or directly to the machines, depending on the setup. The pipelines branch off to feed multiple machines simultaneously, ensuring each machine receives a continuous, precise supply of material. The system uses air locks and filters to prevent contamination and dust buildup during transport. This method eliminates manual handling and reduces material waste.

At each injection molding machine, a hopper loader or material receiver collects the conveyed resins. Some setups include local drying hoppers to remove moisture immediately before molding, which is critical for hygroscopic plastics like PET or nylon. The system can also integrate gravimetric blenders to mix virgin and recycled materials accurately, ensuring consistent product quality. Sensors monitor hopper levels to avoid shortages, triggering alerts or automatic refills. This integration enables fully automated, unmanned operations where materials are fed continuously without operator intervention, boosting productivity and reducing downtime.

This well-orchestrated process ensures smooth production flow, high material quality, and efficient resource use. By centralizing control and automating material transport, manufacturers can achieve a cleaner workshop environment, reduce labor costs, and maintain consistent molding cycles.

The central feeding system in plastic machinery relies on several critical components working together to ensure smooth, automated material handling. Each part plays a specific role, contributing to the overall efficiency and reliability of the system. Let's explore these key components:

This is the brain of the system. It uses an industrial computer or PLC to coordinate all operations. The console controls material flow, drying cycles, dust collection, and alarms. Operators interact with it via a touchscreen interface to set feeding schedules, monitor system status, and receive alerts. It ensures precise timing and synchronization, enabling 24/7 automated operation without manual intervention.

The cyclone dust collector removes dust and fine particles from the conveyed raw materials. It uses centrifugal force to separate dust from the air stream, preventing contamination and protecting downstream equipment. This component is essential to maintain material purity and extend the life of filters and fans by reducing their load.

After the cyclone collector, the high-efficiency filter traps remaining fine dust to ensure clean air exhaust. The fan creates the necessary airflow and vacuum pressure to transport materials through the pipeline network. These components work together to maintain a consistent vacuum level, ensuring smooth material movement and preventing blockages.

The material selection rack stores multiple raw materials or additives, allowing operators to choose specific types for different production runs. The branch station connects the main pipeline to individual branch lines leading to each injection molding machine. It controls which material flows to which machine, enabling flexible and precise distribution.

Many plastics require drying before processing to remove moisture that can cause defects. The drying hopper holds material while heated air passes through it, drying the resin. The dehumidifier supplies dry air by removing moisture from the environment. Together, they ensure materials are properly conditioned before molding, improving product quality.

Tip: Regularly clean and maintain the cyclone dust collector and high-efficiency filters to prevent airflow reduction and ensure consistent material conveying performance.

The central feeding system offers several standout features that make it indispensable in modern plastic manufacturing. These features focus on boosting efficiency, saving energy, centralizing control, and providing customization to fit unique industrial needs.

The system automates raw material supply to many injection molding machines across different chambers. It handles complex tasks like drying raw materials, matching colors, and recycling materials proportionally. This automation supports nonstop production, 24/7, reducing manual labor and human error. Operators can rely on the system to keep material flow steady and consistent, which is vital for maintaining product quality and meeting high output demands.

By centralizing material handling, the system cuts down the need for multiple dryers or loaders near each machine. This reduces overall power consumption and lowers maintenance costs since fewer standalone units operate independently. Additionally, the design frees up valuable floor space around the machines, allowing for better workshop layout and easier movement. The system’s energy-saving design also helps companies meet sustainability goals by reducing their carbon footprint.

Raw materials are stored and managed in a dedicated central area, separated from the molding machines. This separation simplifies material handling and reduces contamination risks, creating a cleaner production environment. Centralized control means operators can monitor and adjust the entire feeding process from one location, improving oversight and response times. The cleaner setup also helps maintain compliance with industry standards for hygiene and safety.

Every plastic manufacturing environment has unique demands. The central feeding system offers flexible configurations to meet these needs. Whether a factory processes standard resins or requires special handling for recycled or color-matched materials, the system can be tailored accordingly. This customization extends to layout design, equipment selection, and control software, ensuring the system integrates smoothly into existing workflows and scales as production grows.

Designing an efficient central feeding system layout is key to ensuring smooth, uninterrupted production in plastic machinery workshops. A well-planned layout optimizes material flow, reduces downtime, and simplifies maintenance. Here's a step-by-step guide to creating a practical and effective layout.

Start by understanding your workshop's size and how your machines are arranged. Consider:

● Number of injection molding machines

● Machine layout: single row, double row, or U-shape

● Available space for central raw material storage and equipment

Arranging machines in rows or groups helps shorten pipeline lengths and simplifies material distribution. This approach reduces installation costs and improves system efficiency.

This area is the starting point for all raw materials. It typically includes:

● Bulk bag unloading or manual bag dump stations

● Material silos or multi-bin hoppers

● Optional pre-mixing units for blending virgin and recycled materials

Choose a location that allows easy forklift access and minimal disruption to production flow. Centralizing raw materials here makes handling easier and reduces contamination risks.

For hygroscopic plastics like PET or nylon, drying is essential. Position dryers and dehumidifiers:

● Between the raw material storage and distribution network

● Close to machines if drying smaller batches

● In well-ventilated areas to release hot air safely

A typical setup uses one central dehumidifying dryer connected to multiple drying hoppers. This ensures materials are properly conditioned before molding, improving product quality.

The vacuum pipeline is the system's backbone. Key design tips include:

● Use vacuum pump stations to create suction

● Install stainless steel pipes for durability and cleanliness

● Include material distribution valves and dust filters

● Keep pipes as short and straight as possible

● Avoid sharp bends and long horizontal runs to prevent blockages

● Use color-coded or labeled pipes for easy identification

A well-designed pipeline network delivers materials smoothly to each machine, ensuring continuous feeding.

At each machine, install:

● Material receivers or hopper loaders to collect materials

● Mini dryers if local drying is needed

● Low-level sensors to prevent material shortages

● Optional gravimetric blenders for precise mixing of virgin and recycled materials

These components guarantee that each machine receives the right material at the right time, maintaining production quality and efficiency.

A centralized control panel with PLC and touchscreen interface allows:

● Real-time monitoring of material flow and system status

● Automatic alerts for errors or pipe blockages

● Scheduling of feeding times and material types per machine

For advanced setups, add remote monitoring or data logging to integrate with smart factory systems. This centralized control simplifies management and speeds up troubleshooting.

Central feeding systems bring numerous benefits to plastic manufacturing plants, transforming how raw materials are handled and delivered. These systems optimize production by ensuring continuous material distribution, reducing downtime, and automating labor-intensive tasks. Here's a detailed look at their key advantages:

Central feeding systems keep raw materials flowing steadily to each injection molding machine. This uninterrupted supply prevents stoppages caused by material shortages, helping maintain consistent production cycles. By automating material delivery through vacuum or pressure pipelines, the system eliminates manual loading delays and reduces the risk of human error.

The system's automation and monitoring features detect issues early, such as blockages or low hopper levels, allowing quick corrective action. This proactive management minimizes machine downtime and keeps production running smoothly. Centralized control panels provide real-time status updates, so operators can respond swiftly to alarms or irregularities.

By automating tasks like material conveying, drying, and blending, the system significantly cuts labor needs. Operators no longer need to manually handle raw materials at each machine, freeing them to focus on other production aspects. This reduces labor costs, lowers fatigue-related errors, and enhances safety by minimizing material handling in the workshop.

Central feeding systems can be tailored to fit specific production requirements, including various raw materials, batch sizes, and machine layouts. Custom options allow integration of features like gravimetric blenders for precise mixing, multiple material selection racks, or specialized drying setups. This adaptability ensures the system meets unique manufacturing challenges and scales with production growth.

Centralizing material storage and handling frees up floor space around injection molding machines, improving workshop layout and workflow. The system’s sealed pipelines and dust collectors reduce contamination risks, creating a cleaner and safer environment. This hygienic setup supports compliance with industry standards and enhances product quality by preventing impurities.

Central feeding systems enhance plastic manufacturing by automating material delivery, reducing labor and downtime, and ensuring consistent production. These systems offer future-proof solutions, adapting to unique manufacturing needs and scaling with production growth. Automation and efficiency are key benefits, optimizing space and maintaining a hygienic environment for improved product quality. Jwell provides advanced central feeding systems that deliver exceptional value, supporting manufacturers in achieving seamless operations and meeting high production demands.

A: A central feeding system automates the delivery of raw materials to multiple processing machines, ensuring a steady supply of plastic resins and additives, improving efficiency, and reducing manual labor.

A: The system operates through a central control console, material transportation via pipelines, and integration with molding machines, ensuring continuous, automated material supply without manual intervention.

A: It offers automation, consistent material flow, reduced labor costs, minimized downtime, space optimization, and a cleaner production environment, enhancing overall manufacturing efficiency.

A: Essential components include the central control console, cyclone dust collector, high-efficiency filter and fan, material selection rack, branch station, drying hopper, and dehumidifier.

A: By automating material handling, ensuring consistent quality, reducing manual tasks, and integrating auxiliary equipment, it boosts productivity and maintains uninterrupted manufacturing cycles.