- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-09-16 Origin: Site

Have you ever wondered what happens when plastic melts? Understanding plastic’s melting point is key to many industries.

In this post, we’ll explore the melting points of common plastics and their impact on manufacturing processes. You’ll also learn how plastic rigid pelletizing machines are crucial for efficiently processing plastic materials.

The melting point of plastic is the temperature at which the material transitions from a solid to a liquid. This is an important property for plastics used in manufacturing and recycling processes.

Melting points affect the processing temperature for plastics. Plastics are often heated to their melting point during molding or extrusion. It’s crucial to control this temperature to avoid degradation or uneven melting.

● Manufacturing: Precise control over temperature ensures efficient molding, preventing defects.

● Recycling: Knowing the melting point helps optimize plastic recycling processes, ensuring high-quality recycled products.

● Quality Control: Maintaining the correct melting temperature ensures uniformity in plastic products, reducing waste.

Different plastics have different melting points, which is why understanding these temperatures is essential for machines like plastic rigid pelletizing machines. These machines rely on the right melting points to create high-quality plastic pellets during recycling.

High-Density Polyethylene (HDPE) is a type of plastic made from polymerizing ethylene. It’s known for its strength, durability, and resistance to impact. HDPE is widely used in packaging, plumbing, and even automotive parts.

Key Characteristics of HDPE:

● High strength-to-density ratio

● Resistant to impact and wear

● Good chemical resistance

The melting point of HDPE typically ranges from 120-130°C (248-266°F). This makes it suitable for applications that require a higher resistance to heat.

HDPE’s relatively high melting point allows it to withstand harsh conditions. This makes it ideal for products like:

● Plastic pipes (resistant to heat and pressure)

● Milk bottles (maintains shape and integrity in cold storage)

● Detergent containers (withstand chemicals and heat during use)

Knowing HDPE’s melting point is essential for efficient plastic processing, ensuring the material doesn’t degrade or melt improperly during manufacturing.

Plastic rigid pelletizing machines are designed to handle HDPE’s high melting point by carefully controlling temperature during the pelletizing process. The extruder and screw mechanism maintain the required heat to fully melt HDPE without causing degradation. This is crucial for ensuring high-quality pellets for further use in manufacturing.

The higher melting point of HDPE provides several advantages:

● Improved Durability: Pellets made from HDPE maintain strength even after multiple processing cycles.

● Efficient Processing: The plastic rigid pelletizing machine can optimize the process for HDPE’s specific needs, ensuring smooth extrusion and quality output.

● Reduced Defects: Proper temperature control prevents unwanted defects, like weak spots, during pelletizing.

This makes HDPE a preferred material in industries requiring high heat resistance, and pelletizing machines are crucial in ensuring the material’s integrity.

Low-Density Polyethylene (LDPE) is a flexible and lightweight plastic. It's made from polymerized ethylene, but with a different molecular structure compared to HDPE. This structure gives it unique characteristics that make it suitable for various applications.

Key Characteristics of LDPE:

● Flexible and lightweight

● Low-density molecular structure

● Resistant to impact and moisture

Common Uses:

● Plastic bags

● Plastic films

● Food packaging

● Cling films

LDPE is primarily used where flexibility and ease of processing are important.

LDPE has a relatively low melting point compared to other plastics. The typical range is 105-115°C (221-239°F). This allows it to be processed at lower temperatures, making it ideal for applications like film extrusion.

The lower melting point of LDPE is due to its molecular structure. Unlike HDPE, LDPE has branched polymer chains instead of tightly packed molecules. This makes it less crystalline and more flexible, leading to a lower melting point.

Impact on Plastic Processing:

● Faster processing: LDPE melts quickly, making it ideal for fast extrusion processes.

● Flexibility: The lower melting point allows for more flexibility in molding and forming plastic products.

When handling LDPE in a plastic rigid pelletizing machine, adjustments need to be made for its lower melting point:

● Temperature control: The machine must operate at a lower temperature range to avoid overheating LDPE and causing degradation.

● Processing speed: LDPE can melt quickly, so machines need to ensure even melting without compromising the material’s quality.

● Extruder settings: The screw and barrel design may need to be optimized for LDPE to prevent overheating or incomplete melting.

These considerations ensure the production of high-quality pellets that maintain the properties of LDPE.

Polypropylene (PP) is a versatile plastic made from polymerizing propylene. It is known for its strength-to-weight ratio and heat resistance, making it ideal for tough applications.

Key Characteristics of PP:

● High strength-to-weight ratio

● Excellent heat resistance

● Chemical and moisture resistance

● Lightweight and durable

PP is widely used in a variety of products such as automotive parts, textiles, and food containers due to its unique properties.

The typical melting point of Polypropylene (PP) ranges from 160-170°C (320-338°F). This higher melting point allows PP to withstand heat and pressure in many industrial applications.

PP's higher melting point is due to its crystalline structure. The tightly packed polymer chains contribute to its strength and resistance to heat. This makes it suitable for applications where higher heat resistance is essential, such as:

● Automotive parts (engine components)

● Food containers (microwave-safe containers)

● Medical supplies (sterilizable equipment)

When pelletizing PP in a plastic rigid pelletizing machine, the higher melting point must be carefully managed. The machine must maintain a consistent and controlled temperature to melt PP without degrading it.

How PP’s Melting Point Impacts the Pelletizing Process:

● Precise temperature control: The machine must ensure PP reaches its melting point without exceeding it, avoiding overheating.

● Slower heating process: Due to its higher melting point, the heating process for PP may take longer than for plastics like LDPE or HDPE.

● Optimized extrusion settings: The pelletizing machine must be calibrated to ensure the PP material is fully melted and extruded without defects.

By managing these factors, the plastic rigid pelletizing machine ensures that PP pellets are of high quality and ready for further use in production.

Polystyrene (PS) is a widely used plastic made from the polymerization of styrene. It is known for its brittle nature and versatility in a variety of products. PS can be either solid or foam (expanded polystyrene or EPS), which makes it adaptable for different applications.

Key Characteristics of PS:

● Brittle: Prone to cracking under stress

● Transparent: Often clear, allowing for visual appeal

● Lightweight: Especially in foam form

● Inexpensive: Cost-effective for mass production

Common Uses:

● Disposable cutlery (plates, forks, spoons)

● Foam packaging (protective material for fragile items)

● Insulation (EPS used in construction)

The typical melting point of polystyrene (PS) ranges between 100-110°C (212-230°F). This relatively low melting point makes it easier to process at lower temperatures, but it also means PS can be more easily damaged if exposed to heat for too long.

Polystyrene is used in several everyday items like disposable cutlery, food containers, and foam packaging. Its lower melting point is critical for:

● Foam packaging (EPS): The lower temperature allows for the material to be molded easily into foam sheets and packaging without deformation.

● Disposable items: Items like cutlery and plates are made efficiently at lower temperatures, saving energy in production.

● Insulation: EPS is often used in insulation, benefiting from its easy moldability and heat resistance at lower temperatures.

Knowing the melting point of PS helps manufacturers set the right temperature for processing, ensuring products maintain their integrity and function.

When processing PS in a plastic rigid pelletizing machine, its lower melting point requires specific adjustments. The machine must:

● Control temperature: Lower temperatures are needed to melt PS without causing degradation.

● Use slower heating settings: To avoid overheating PS and reducing the quality of pellets.

● Prevent overheating: Excessive heat can cause PS to lose its structural integrity, resulting in poor pellet quality.

By managing these factors, pelletizing machines can efficiently process PS while maintaining the desired properties for its various applications.

Acrylonitrile-Butadiene-Styrene (ABS) is a high-strength thermoplastic made from three components: acrylonitrile, butadiene, and styrene. Known for its toughness and durability, ABS is widely used in manufacturing durable, high-quality products.

Key Properties of ABS:

● Impact resistance: Strong resistance to physical damage and stress.

● Toughness: Excellent for products that need to withstand rough handling.

● Heat resistance: Can endure higher temperatures than many other plastics.

Common Uses of ABS:

● Electronics housings (e.g., computer and TV cases)

● Toys (such as Lego bricks)

● Automotive parts (dashboards, wheel covers)

The melting point of ABS typically ranges from 210-240°C (410-464°F). This higher temperature range makes it suitable for high-performance applications where strength and heat resistance are important.

ABS’s high melting point is due to its crystalline structure and chemical composition. The strong molecular bonds between acrylonitrile, butadiene, and styrene provide enhanced heat resistance. This is why ABS is often used in products exposed to higher temperatures.

Importance of ABS’s Melting Point in Manufacturing:

● Strength: The ability to withstand high temperatures is crucial for producing durable parts.

● Stability: The high melting point ensures products maintain their shape and strength even under stress.

When pelletizing ABS, the high melting point requires careful control during the processing. The plastic rigid pelletizing machine must:

● Maintain precise temperature: Ensure the plastic reaches the correct melting point without degrading.

● Manage cooling rates: Slow and controlled cooling is necessary to maintain the material’s strength and integrity.

● Use specific screw designs: Specialized screws help handle the high viscosity of melted ABS.

These considerations ensure that ABS pellets maintain the necessary strength and quality for further applications.

Polycarbonate (PC) is a high-performance thermoplastic known for its exceptional strength and transparency. Made from a polymerization of bisphenol A (BPA), it is used in products requiring high impact resistance and optical clarity.

Key Properties of Polycarbonate:

● Impact resistance: Extremely durable, even in cold conditions.

● Optical clarity: Offers glass-like transparency while being much lighter.

● Heat resistance: Performs well at higher temperatures compared to many plastics.

Common Uses of Polycarbonate:

● Safety goggles (resistant to breakage and impact)

● Optical lenses (used in eyewear, camera lenses)

● Automotive parts (headlight covers, dashboards)

Polycarbonate has a relatively high melting point, typically ranging from 220-230°C (428-446°F). This higher melting point allows PC to withstand extreme temperatures, making it suitable for demanding applications.

PC’s high melting point is essential for products exposed to heat, such as:

● Safety goggles: Protects against heat and impact in hazardous environments.

● Optical lenses: Maintains clarity and shape at elevated temperatures.

● Automotive parts: Ensures components like headlamp covers stay intact even when exposed to high heat.

The high melting point of polycarbonate ensures these products maintain their performance, shape, and clarity under heat stress.

When pelletizing polycarbonate (PC), the plastic rigid pelletizing machine must carefully manage its higher melting point. The machine must:

● Ensure precise temperature control: Too much heat can degrade the material, affecting its optical properties.

● Maintain a slow cooling rate: Gradual cooling helps preserve the material’s strength and clarity.

● Use specialized equipment: The screw and barrel design must handle PC's viscosity and maintain the required temperatures for melting.

These adjustments ensure that PC pellets maintain the necessary characteristics for use in high-performance applications.

The molecular structure of a plastic plays a significant role in determining its melting point. Plastics consist of long chains of molecules that can be arranged in different ways, affecting their properties.

Crystalline vs. Amorphous Structure:

● Crystalline Plastics: Molecules are tightly packed, forming a regular structure. This leads to higher melting points, as more energy is required to break these bonds. Examples: HDPE.

● Amorphous Plastics: Molecules are arranged randomly, which makes them easier to melt at lower temperatures. Examples: PS, LDPE.

The way these molecules are organized directly impacts the amount of heat needed for the plastic to change from solid to liquid.

Additives play a crucial role in adjusting the melting behavior of plastics. They are often mixed into the base polymer to enhance or alter certain properties, including melting temperature.

Common Additives and Their Effects:

● Stabilizers: These help maintain the integrity of the polymer during processing, preventing premature degradation at high temperatures. They can raise the melting point.

● Plasticizers: Added to increase flexibility, plasticizers often lower the melting point by reducing intermolecular forces, making the plastic more pliable at lower temperatures.

● Fillers: Materials like glass fibers can also be added to increase the strength of a plastic, often influencing the temperature at which it melts.

These additives allow manufacturers to tailor the plastic's melting point for specific applications.

The density of a plastic and how it is polymerized also affects its melting point. Plastics can be classified based on their molecular density and the way the polymer chains are linked together.

How Density and Polymerization Influence Melting Points:

● Higher Density: Materials with a high-density structure tend to have higher melting points due to the stronger forces between the molecules. Example: HDPE.

● Polymerization Type: Cross-linked polymers (like some thermosets) have a more rigid structure, preventing them from melting in the traditional sense. This leads to higher thermal stability.

For Plastic Rigid Pelletizing Machines, knowing how these factors affect melting points is crucial. The machines need to adjust for different plastic types by modifying the heat settings, screw design, and cooling rates to maintain high-quality pellets during the extrusion process.

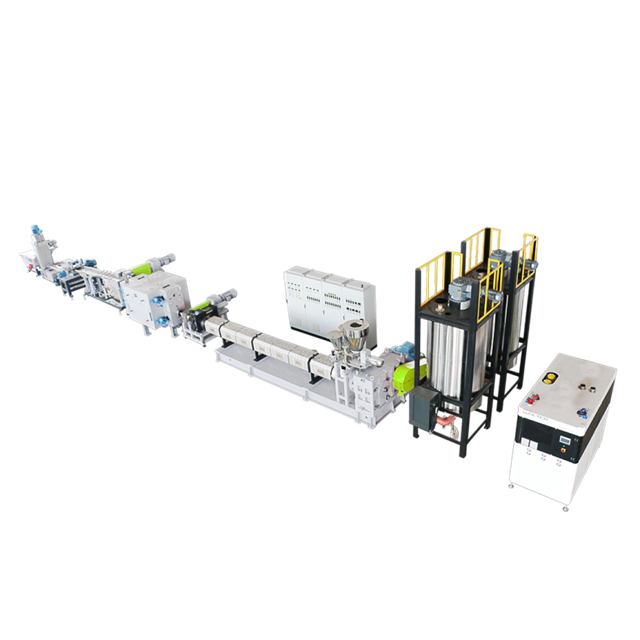

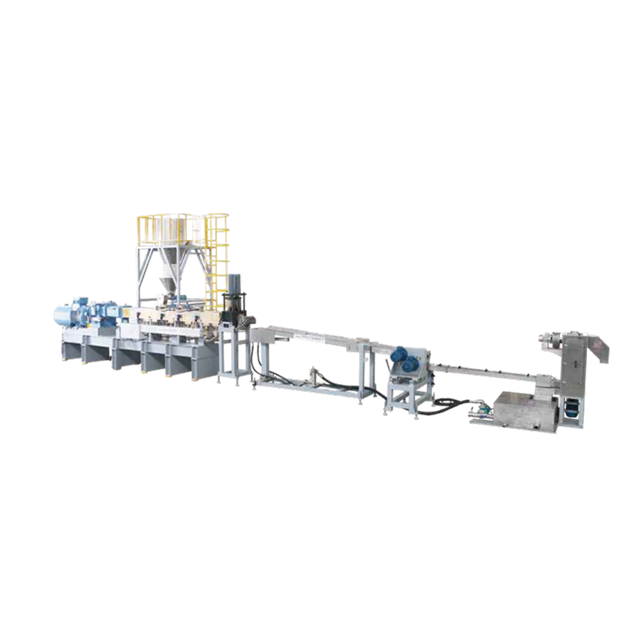

A plastic rigid pelletizing machine is used in the recycling and manufacturing of plastic materials. It turns raw plastic into small, uniform pellets that can be used in various production processes. These machines are essential in industries like recycling, plastic manufacturing, and material processing.

Key Roles of Plastic Pelletizing Machines:

● Recycling: Turning waste plastic into reusable pellets.

● Manufacturing: Converting raw plastic into usable forms for further production.

● Material Processing: Ensuring plastic materials are appropriately processed for quality and consistency.

The process involves several critical steps, each designed to ensure the plastic is properly processed into usable pellets.

1. Feeding: Raw plastic is fed into the machine.

2. Melting: The plastic is heated until it reaches its melting point, making it soft and moldable.

3. Extruding: The melted plastic is forced through a die to form a long strand.

4. Cutting: The strand is cut into small pellets of consistent size.

This continuous cycle ensures that plastic is turned into uniform pellets ready for further use in the manufacturing process.

Temperature control is crucial during pelletizing. The machine must heat the plastic to the right temperature—different plastics have different melting points. If the temperature is too high or too low, it can lead to issues like:

● Degradation of the plastic

● Inconsistent pellets with defects

● Energy waste from improper temperature settings

By precisely managing the heat, plastic rigid pelletizing machines ensure smooth, efficient production and high-quality output.

A plastic rigid pelletizing machine relies on a well-designed screw mechanism to process plastic efficiently. The screw design is tailored to create specific heat zones, each controlling the temperature at different stages of the process. These zones ensure that the plastic is heated gradually and consistently, preventing overheating or underheating.

Key Considerations:

● Temperature zones: Different sections of the screw manage the plastic's temperature at each stage.

● Heat distribution: Ensures uniform melting without damaging the material.

Plastic pellets must be free from impurities to maintain high quality. Filtration removes contaminants, and degassing systems ensure no unwanted gases or moisture are trapped in the pellets.

Why These Features Matter:

● Filtration: Prevents impurities from affecting pellet quality.

● Degassing: Ensures a smooth, defect-free surface for each pellet.

These systems ensure that the final pellets are clean and ready for use in further manufacturing.

Each type of plastic has its own melting point and processing characteristics. Plastic rigid pelletizing machines must be adjusted to handle these variations effectively. This means modifying the heating, extrusion, and cooling systems to ensure the plastic is processed correctly.

Example Adjustments:

● HDPE: Requires higher temperatures for melting.

● LDPE: Needs lower temperatures and quicker processing speeds.

To produce high-quality pellets for each plastic type, the machine must adapt to the specific properties of the material. Adjustments may include:

● Temperature: Setting the right heat level for optimal melting.

● Screw speed: Adjusting the speed to ensure the plastic flows smoothly and consistently.

This precise control guarantees the quality and consistency of the pellets, ensuring they are suitable for various applications.

Plastic rigid pelletizing machines play a pivotal role in recycling plastic waste. These machines transform used plastic into reusable pellets that can be used for manufacturing new products. The process involves melting the plastic waste, forming it into strands, and cutting it into small, uniform pellets.

How Plastic Pelletizing Machines Aid in Recycling:

● Collection of Plastic Waste: Collects plastic waste from various sources, including post-consumer products.

● Melting and Processing: The machine melts the plastic waste, removing impurities, and then shapes it into pellets.

● Reusability: The pellets can be reused in production, reducing the need for virgin plastic materials.

This process is crucial for recycling programs, helping to reduce environmental impact and ensuring that plastic waste is repurposed effectively.

Plastic rigid pelletizing machines are integral to several industries that rely on plastic products for production. From everyday household items to automotive parts, these machines help in creating the precise plastic forms required for various applications.

Examples of Industries That Rely on Plastic Pelletizing Machines:

● Automotive: Components like dashboards, bumpers, and under-the-hood parts.

● Packaging: Bottles, containers, and flexible films.

● Electronics: Housings for devices like phones and computers.

Each of these industries depends on the quality and uniformity of plastic pellets produced by pelletizing machines to maintain high standards in their manufacturing processes.

Plastic rigid pelletizing machines contribute significantly to sustainability in the plastic industry. By turning waste plastic into new pellets, they help reduce the consumption of virgin plastic, leading to less plastic waste in landfills and oceans.

How Pelletizing Machines Support Sustainability:

● Waste Reduction: Recycling and reusing plastic reduces the need for new plastic production.

● Energy Efficiency: Many modern machines are designed to be energy-efficient, reducing the carbon footprint of plastic processing.

● Circular Economy: Promotes the circular economy by ensuring plastic is reused rather than discarded, reducing overall environmental impact.

By enabling recycling and reducing the need for raw materials, plastic rigid pelletizing machines play a crucial role in achieving sustainability goals within the plastic industry.

When selecting a plastic rigid pelletizing machine, one of the most important factors is its capacity and the scale of operation. The size and throughput of the machine should align with the volume of plastic you plan to process.

Small-Scale vs. Industrial-Scale Machines:

● Small-Scale Machines: Suitable for small businesses or pilot projects, processing a lower volume of material.

● Industrial-Scale Machines: Designed for large-scale operations, capable of handling high volumes of plastic waste or production.

Choosing the right machine based on your needs ensures efficient production and minimizes costs.

The type of plastic you plan to process is another crucial consideration. Not all plastic pelletizing machines are compatible with every type of plastic.

Material Compatibility Considerations:

● Plastic Types: Ensure the machine can handle the plastics you want to recycle or process, such as HDPE, PP, PS, or ABS.

● Additives: Some machines are designed to handle plastics with additives like fillers or plasticizers, while others may not.

Understanding the compatibility of the machine with your material is essential to prevent damage and ensure efficient processing.

Modern plastic rigid pelletizing machines often come equipped with automation and control systems. These systems offer significant advantages in terms of production efficiency and product quality.

Benefits of Automation and Control:

● Precision: Automated systems allow for exact temperature, pressure, and speed control, which improves consistency.

● Efficiency: Reduces the need for manual adjustments, leading to higher throughput and less downtime.

● User-Friendly: Many machines come with user-friendly interfaces (e.g., PLCs or HMIs) for easy monitoring and adjustments.

These systems enable smooth, reliable operations and reduce human error during the pelletizing process.

Choosing a machine that is easy to maintain is crucial for ensuring long-term efficiency and cost-effectiveness. Machines that require frequent repairs can be expensive and reduce productivity.

Key Factors Affecting Maintenance and Longevity:

● Durability of Parts: Look for machines made with high-quality materials like stainless steel and special alloys for longer lifespan.

● Ease of Maintenance: Machines with modular components or accessible parts make it easier to perform regular checks and replacements.

● Wear Resistance: Machines that are designed to handle various plastics without excessive wear ensure better longevity.

Regular maintenance helps avoid costly repairs and keeps your pelletizing machine running at peak performance.

Purchasing a plastic rigid pelletizing machine involves an initial investment, but over time, the savings generated can make it a cost-effective solution for your business. While the upfront cost may seem significant, these machines often pay for themselves through improved efficiency and reduced operational costs.

Key Savings Factors:

● Reduced Material Waste: By recycling plastic, you avoid purchasing raw materials, cutting down on material costs.

● Energy Savings: Advanced machines offer features that reduce energy consumption, lowering overall operational costs.

● Less Labor: Automation reduces the need for manual labor, further lowering costs.

When comparing the cost of purchasing the machine to the long-term savings, it’s clear that the benefits often outweigh the initial expenditure, making these machines a sound investment.

Many plastic rigid pelletizing machines come with energy-efficient features designed to minimize energy consumption while maintaining optimal performance. These features not only make them more sustainable but also more affordable to operate in the long run.

Energy-Efficient Features in Pelletizing Machines:

● Friction Heating: This feature allows the machine to heat plastic efficiently, reducing the need for external heating sources. It saves both energy and costs.

● Automated Temperature Control: By precisely controlling the temperature during the pelletizing process, the machine ensures optimal energy use, preventing overheating or underheating, both of which waste energy.

These features make plastic pelletizing machines a more cost-effective and sustainable choice for businesses, offering lower energy consumption while still delivering high-quality output.

We explored the melting points of common plastics and the crucial role of plastic rigid pelletizing machines in processing these materials. These machines are key to converting waste plastic into reusable pellets.

Selecting the right pelletizing machine is essential for matching the plastic type, processing capacity, and industry needs to ensure high-quality output.

Efficient plastic recycling reduces waste, and plastic rigid pelletizing machines play a vital role in minimizing environmental impact.