- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Ever wonder what happens to all those plastic bottles and polyester clothes?

PET plastic is everywhere—from drink bottles to t-shirts.

But it causes serious waste problems.Recycling PET helps reduce pollution and saves resources.

In this post, you'll learn what PET recycling is, why it matters,

and how plastic rigid pelletizing machines make it all possible.

PET plastic—found in bottles, trays, and clothes—doesn't just disappear after use.

It goes through several steps before becoming reusable again.

PET waste comes from almost everywhere.

You’ll see it in:

● Households: soft drink bottles, packaging trays, containers

● Businesses: food service packaging, textile waste, retail hangers

● Industries: synthetic fibers, straps, films, bulk packaging

These items are collected through:

● Local recycling programs

● Drop-off centers

● Industrial plastic recovery facilities

Collection is the foundation. Without enough PET waste, recycling can’t happen.

Not all plastic is PET. That’s why sorting matters.

There are two main ways:

Method | How it Works | Good For |

Manual Sorting | Workers pick PET from other waste | Small-scale operations |

Automated | Machines use NIR, sensors, AI | High-volume facilities |

If PET is mixed with other materials—PVC, labels, food residue—it hurts the recycling outcome.

Even 1% contamination can ruin a whole batch of pellets.

So, we separate clean from dirty, PET from non-PET, clear from colored.

It all starts here.

Once sorted, PET goes into industrial shredders.

These machines slice bottles and trays into flakes—small pieces that are easier to clean and melt.

Shredder blades must stay sharp.

Blunt blades make uneven flakes. Uneven flakes = bad pellets.Why does flake size matter?

● Too large → melts unevenly, causing lumps

● Too small → overmelts or burns during extrusion

● Inconsistent → leads to pressure fluctuation at the die head

Clean, dry, and uniform flakes = perfect input for plastic rigid pelletizing machines.

PET flakes carry dust, glue, and leftover drinks or food.

These contaminants must go.

Washing systems use:

● Friction washers – scrub the flakes

● Hot water tanks – loosen labels

● Chemical baths – remove sticky glue

After washing? Drying comes next.

Even a little moisture can cause foaming or bubbles in the plastic during extrusion.

Drying equipment includes:

● Hot air dryers

● Infrared dryers

● Centrifugal dryers

This step prepares the flakes for pelletizing.

Dry flakes melt evenly and make stronger, cleaner pellets.

Plastic recycling doesn’t end after cleaning and drying PET flakes.

To make them truly useful again, we need to transform them into something better—pellets.

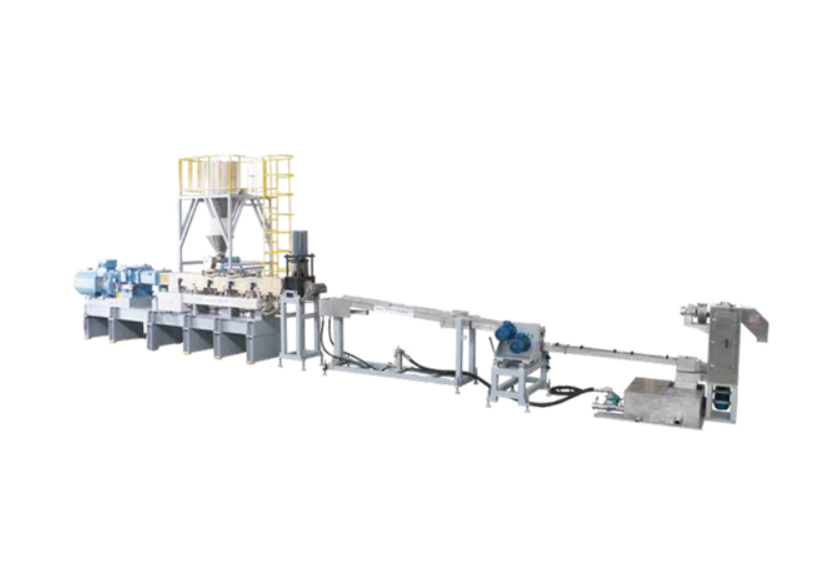

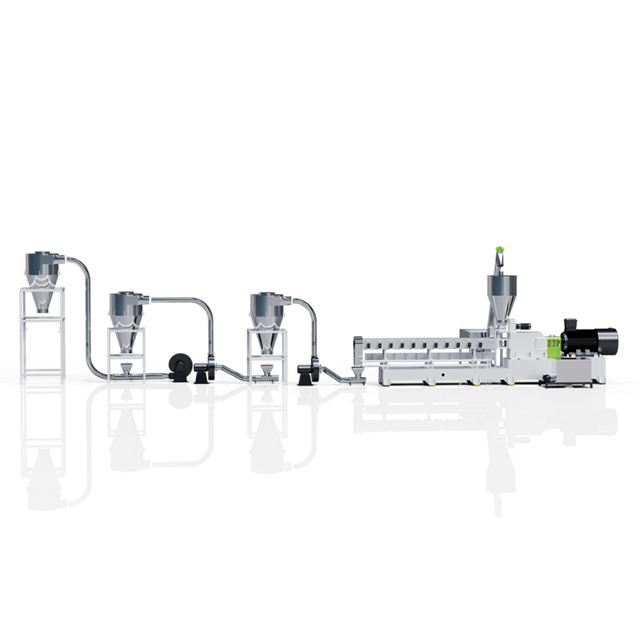

A plastic rigid pelletizing machine is the heart of the PET recycling line.

Its job? Turn washed, dried PET flakes into small, clean, uniform pellets.

These pellets are easier to sell, ship, and reuse in manufacturing.This machine handles:

● Heating the plastic

● Filtering out leftover impurities

● Forming consistent pellet shapes

It’s not just a helper—it’s essential for making high-quality, recycled PET.

Here’s how plastic rigid pelletizing machines convert flakes into pellets:

Step | What Happens |

1. Feeding | Clean PET flakes are loaded into the machine hopper |

2. Melting | Internal heaters melt the flakes into thick, molten plastic |

3. Filtering | Fine mesh screens remove tiny bits of dirt or leftover glue |

4. Extrusion | Melt is pushed through a die to form long strands or droplets |

5. Cutting | Spinning knives chop the melt into small pellet shapes |

6. Cooling | Water or air cools the pellets quickly for hardening |

Each part of this process is important, but the die and cutter do most of the shaping work.

● Extrusion Die: Controls pellet size and shape

It acts like a mold—material is pushed through tiny holes.

● Cutting Mechanism:

Can be a strand cutter, water-ring blade, or underwater cutter, depending on setup.If the die holes are too wide or pressure is unstable, pellets come out uneven.

If the cutter isn’t fast enough, pellets clump or stretch.That’s why pressure control and screw design matter.

They keep the flow even so the die and cutter can do their job.

PET pellets are the universal currency of recycled plastic.

They’re used in almost every application—from making new bottles to clothes and packaging.

Here’s why pellets are better than flakes:

Feature | Flakes | Pellets |

Flowability | Poor – stick together | Excellent – pour like grains |

Storage Efficiency | Bulky, uneven shapes | Compact and stackable |

Melting Consistency | Uneven due to flake variation | Uniform – melts smoothly |

Market Value | Lower – fewer buyers | Higher – ready for factories |

Pellets give PET a second life.

Without pelletizing machines, recycling stops halfway.

Not all pelletizing machines are built the same.

Some are designed for small labs. Others handle tons of PET every hour.

Let’s look at the key features that make plastic rigid pelletizing machines reliable for recycling.

Large-scale PET recycling plants demand serious throughput.

Most plastic rigid pelletizing machines process between 100 kg/h and 1000+ kg/h.

Why does this matter?

● Keeps up with mass flake production

● Reduces bottlenecks in downstream operations

● Matches the scale of industrial PET usage

Ideal Users:

Facility Type | Recommended Capacity |

Small Recyclers | 100–300 kg/h |

Mid-Sized Plants | 300–700 kg/h |

Industrial Facilities | 800+ kg/h |

More output means more recycled plastic gets back into use—faster.

Clean plastic in = better pellets out.

But even after washing, PET flakes can carry tiny particles.So how do pelletizing machines clean up molten plastic?

They use multi-stage filters:

Filter Stage | Mesh Size | Function |

First Stage | ~60 mesh | Removes larger impurities |

Second Stage | 80–100 mesh | Captures finer particles |

Each screen acts like a net—catching dirt before it reaches the pellet cutter.

Without proper filtration?

● Pellets might have black specs or gas bubbles

● Customers may reject them

● Machines could clog or wear out faster

Filtering is invisible, but critical.

Molten PET often contains unwanted gases.

Moisture, ink, or even bits of cleaning agents get trapped during earlier stages.This is where vacuum degassing comes in.

● Prevents bubbles in pellets

● Stops foaming during extrusion

● Improves strength and surface finish of final pellets

Types of Degassing Systems:

● Vacuum vents near the screw zone

● Water-ring exhaust pumps

These pull out gases, cool them in a cylinder, and trap any residues in water.If PET isn’t degassed properly, pellets may look cloudy or fail during molding.

Degassing = invisible quality control.

The screw is the engine of the pelletizing machine.

It moves, melts, and mixes PET flakes.But not every screw works for every material.

Parameter | Effect on Operation |

Diameter | Affects pressure and output volume |

Pitch | Controls how fast flakes move through the barrel |

Length-to-Dia | Impacts melting time and shear rate |

For PET, screws are designed to:

● Create uniform melting

● Avoid thermal degradation

● Handle flakes with low bulk density

Some machines let you swap screws or barrels depending on material type.

That’s a big win for flexible production setups.When designed right, the screw makes everything downstream—filtration, extrusion, pelletizing—work better.

Once PET is melted, it's time to form pellets.

But how those pellets are made depends on the pelletizing method.Different methods fit different goals—speed, shape, smoothness, or size.

This is one of the most common methods used in PET recycling lines.

1. Here’s how it works:Molten PET exits the die holes in small streams

2. A rotating knife cuts the streams into pellets

3. The pellets instantly fall into a ring of cold water

4. Water cools and solidifies the pellet surface

What makes this method special?

● The water ring cools each pellet evenly

● PLC control (programmable logic controller) adjusts cutting speed based on pressure

● Pellets come out smooth and consistent in shape and size

Feature | Benefit |

Surface Cooling | Prevents sticking or deformation |

PLC-Based Speed Control | Maintains pellet size consistency |

Output Quality | Smooth, round, glossy pellets |

Water ring systems are compact, easy to operate, and great for general-purpose rPET.

Sometimes you need custom-sized or shaped pellets.

That’s where strand pelletizing fits best.

How it works:

1. Molten PET is pushed out through a multi-hole die as long strands

2. These strands pass through a cooling water trough

3. After cooling, a strand cutter chops them into pellets

This method is slower than others but offers:

● Precise control over pellet length

● Better for PET blends or additives

● Easier to inspect each strand before cutting

Element | Function |

Water Trough | Gradual strand cooling |

Strand Cutter | Adjustable pellet length |

Open Setup | Allows quick visual inspection |

Ideal for specialty applications, like when shape or length needs to match mold requirements.

This is the most advanced and automated method—perfect for high-output PET recycling.

Instead of cooling after cutting, this method does everything underwater.

Process overview:

● Molten PET is pushed directly into a water-filled chamber

● Rotating blades cut the PET inside this water

● Pellets cool instantly and are carried away in the water stream

Why use underwater pelletizing?

● Fastest cooling among all methods

● Produces highly uniform, well-rounded pellets

● Excellent for large-scale operations

Feature | Advantage |

Submerged Cutting System | Prevents pellet deformation |

Closed Cooling Circuit | Keeps output temperature steady |

Dimensional Stability | Best among all methods |

This setup requires more initial investment but delivers consistent, high-quality results—perfect for industrial rPET producers.

Once PET flakes are transformed by a plastic rigid pelletizing machine, they’re ready for real-world use.

Pellets are the universal format for manufacturing.

Let’s explore where they go and why industries prefer them.

Recycled PET pellets—often called rPET—can be used in many industries.

From packaging to fashion, they’re everywhere.

Old PET bottles become new ones.

rPET pellets are melted and blown into preforms, then reshaped into new bottles.Why it’s popular:

● Meets food-grade standards

● Saves virgin plastic production

● Supports circular economy goals

PET is also the base material for synthetic fabric.

rPET pellets are melted and spun into polyester yarn, used in:

● Clothing

● Carpet backing

● Upholstery

● Outdoor gear

This is one of the largest markets for rPET globally.

Manufacturers flatten rPET pellets into clear plastic sheets.

● These are formed into:Food trays

● Clamshell containers

● Blister packs

They offer transparency, strength, and lightweight properties.

Heavy-duty PET straps are made from rPET pellets for:

● Packaging pallets

● Securing building materials

● Bundling large goods

These straps are strong, stretch-resistant, and cost-effective.

Application | Product Example | Benefit |

Bottle-to-Bottle | Drink bottles | Food-safe, sustainable |

Polyester Fiber | T-shirts, backpacks | Lightweight, strong, washable |

Thermoforming Sheets | Produce trays, clamshells | Rigid, clear, recyclable |

Industrial Straps | Pallet wraps, cargo bands | Durable, load-resistant |

Using pelletized PET, rather than flakes or ground plastic, provides big advantages in manufacturing and logistics.

Pellets pour like grains—they don’t clump or jam in hoppers.

They’re easier to move, feed, and weigh during production.

Since they’re filtered and degassed, rPET pellets contain fewer impurities.

● That means:Fewer defects in final products

● Better surface finish

● Lower rejection rates

Pellets have more consistent quality than flakes.

Buyers prefer them because they’re easier to process.

Property | PET Flakes | rPET Pellets |

Bulk Handling | Difficult (irregular size) | Easy (uniform and round) |

Storage Efficiency | Lower | Higher |

Melting Consistency | Uneven | Smooth and predictable |

Resale Market Demand | Moderate | High |

Pellets help manufacturers save time, reduce waste, and increase efficiency across their production lines.

Not all plastic rigid pelletizing machines deliver the same results.

Some focus on speed. Others focus on quality.

Let’s look at how they differ—and what actually matters for PET recycling.

It’s tempting to buy the biggest machine with the highest output rate.

But higher capacity doesn’t always mean better pellets.

Here’s why:

● More speed = less control

● Faster flow = uneven pressure at the die head

● Rushed extrusion = inconsistent pellet shape or trapped gas

If you're producing:

● Food-grade packaging

● Medical plastics

● High-spec polyester yarn

Then purity beats speed every time.

Low contamination levels are critical in these industries.

Priority | Best Machine Type |

Maximum Output | High-capacity, continuous-feed |

Consistent Quality | Multi-stage filtration, stable screw speed |

Clean Appearance | Vacuum degassing + PLC control |

Machines need to match your end-use requirements, not just your production goals.

Energy-saving designs are popular—but sometimes they come at a cost.

You may see machines that:

● Use fewer heating zones

● Run motors at lower RPM

● Have smaller screw barrels

Yes, they save power.

● But what’s the tradeoff?Longer heating time = slower melting

● Incomplete melt = bad extrusion flow

● Overused components = shorter lifespan

A machine that saves 10% on electricity but fails after 2 years

may cost more than one that runs efficiently for 6–8 years.Think long-term:

Feature | Low-Energy Model | Industrial-Grade Model |

Energy Use | Lower | Moderate |

Output Consistency | Variable | High |

Maintenance Frequency | Frequent | Less frequent |

Component Durability | Lower | Higher |

Efficiency is great—if it doesn’t hurt product quality or durability.

Downtime isn’t always visible on a budget sheet.

But it hurts your operation more than you think.Every hour your pelletizer is down:

● Flakes pile up

● Staff sits idle

● Deliveries get delayed

Machines that are hard to service or have rare spare parts can add weeks of delay.

● Modular design

● Access panels for screw and die removal

● Clear operator interface (digital or manual)

● Local availability of parts

Also, don’t forget operator training.

If your team can’t troubleshoot a jam or adjust the pressure—they’ll call for service.

And that means more downtime.

Factor | Impact |

Spare Part Access | Faster repair turnaround |

Simple Screw Removal | Reduces cleanup time |

Training Documentation | Empowers in-house maintenance |

Diagnostic System (PLC) | Helps catch problems early |

Running a PET recycling line isn’t just about having a good machine.

It’s about what you feed it—and how well you maintain it.Let’s look at two practices that make or break pellet quality.

Pelletizing machines don’t fix dirty input.

What goes in affects what comes out.

To get strong, smooth, defect-free pellets:

● Flakes must be clean (free from food, glue, ink)

● Flakes must be dry (moisture causes bubbles and foaming)

● Flakes must be uniform (even size = stable melt)

Here’s how different flake issues affect your output:

Flake Issue | Problem in Pellets |

Oily/dirty surfaces | Poor bonding, black specs |

Moisture > 0.5% | Air pockets, puffed pellets |

Mixed flake sizes | Inconsistent flow, cutter jamming |

● Use hot water + friction washers

● Dry with infrared or centrifugal systems

● Screen out fines and oversize particles before feeding

A plastic rigid pelletizing machine performs best when fed like a pro.

Even the best machine wears out—if you don’t take care of it.

Don’t wait for a breakdown.

Use preventive maintenance to stay ahead of issues.

Component | Common Wear Issues | How to Monitor |

Screws/Barrels | Erosion, poor plasticization | Measure melt temp/pressure |

Filters/Screens | Clogs, increased backpressure | Check pressure readings |

Cutting System | Dull blades, pellet inconsistency | Visual inspection + output |

Vacuum System | Weak suction, gas bubbles | Vacuum gauge performance |

If you notice poor pellet quality—check filters first.

If output slows, look at screw wear.

A machine is only as good as the people using it.

Make sure your team knows:

● How to adjust pressure and speed

● When to clean or change filters

● What signs indicate wear or clogging

● How to shut down safely for cleaning

Use a checklist system for weekly or daily maintenance.

Track hours, part replacements, and error logs with your PLC or manually.Smart maintenance keeps your line running longer, with fewer stops and better output.

PET recycling is no longer just about cleaning and melting plastic.

It’s evolving fast—with smarter machines, stricter rules, and growing market needs.Let’s look ahead at where plastic rigid pelletizing machines are going.

Manufacturers are adding tech that makes machines think, monitor, and improve results in real time.

Sensors inside the extruder can now detect:

● Temperature fluctuation

● Screw wear

● Melt pressure irregularities

● Filter blockages

They alert operators or trigger automatic adjustments.

This means fewer surprises and more uptime.

Sensor Type | What It Detects | Result |

Melt Temp Sensor | Overheating or cold spots | Better melt consistency |

Pressure Transducer | Filter or screw issues | Early warning system |

Vibration Sensor | Motor or blade imbalance | Reduces mechanical failure |

With better monitoring, recyclers waste less material and time.

Artificial intelligence is stepping into the QC process.

How does it help?

● Uses cameras to scan pellet shape and color

● Learns what “defects” look like and flags them

● Suggests adjustments to screw speed or cutter timing

Instead of checking every few hours, the system checks every second.

And the more it sees, the smarter it gets.

This reduces human error and produces more consistent, premium-grade rPET.

Governments and industries are shifting hard toward a circular economy.

This means keeping materials—like PET—in use longer, not throwing them away.

Many regions now require minimum recycled content in packaging.

Country/Region | Regulation Example |

European Union | 25% rPET in bottles by 2025 |

California (USA) | 50% recycled content by 2030 (AB 793 law) |

Canada | Target: 90% recovery rate for beverage PET |

That means:

● Pellet demand is rising

● Quality expectations are higher

● Plastic rigid pelletizing machines must deliver food-safe output

Recyclers that produce consistent, high-purity pellets will win big.

Manufacturers don’t just want “any” rPET—they want pelletized material that meets specs.

Driver | Impact on Pelletizing Tech |

Legal mandates | Higher purity and traceability needed |

Brand sustainability goals | Demand for food-grade rPET |

Consumer awareness | Push for visibly recycled packaging |

PET recycling starts with collection, sorting, cleaning, and flake preparation.

But it doesn’t end there.Plastic rigid pelletizing machines turn flakes into high-quality pellets.

These pellets are easier to sell, transport, and reuse.For recyclers and manufacturers, pelletizing is the key step.

It unlocks true value from recycled plastic.Investing in the right machine means better output—and a cleaner planet.

A: PET flakes are shredded plastic pieces; pellets are melted, filtered, and cut into uniform shapes ready for manufacturing.

A: Flakes are inconsistent in shape and moisture. Pellets are cleaner, uniform, and easier to process in automated production.

A: Prices vary by capacity and features, typically ranging from tens of thousands to hundreds of thousands of dollars.

A: Yes, many models can process various rigid plastics, but screw design and temperature settings must be adjusted.

A: Base it on your desired pellet quality, capacity, cooling needs, and end-use—options include strand, water-ring, and underwater.