- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2026-01-28 Origin: Site

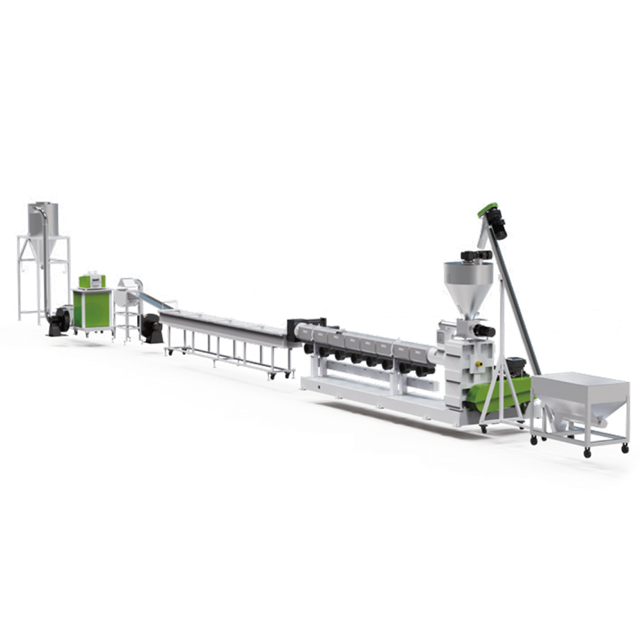

Are you looking for efficient manufacturing solutions? Single screw extruders offer remarkable advantages across various industries. Understanding these benefits can streamline production and reduce costs. In this post, we'll explore the key advantages of single screw extruders and how they can enhance your operations.

A single screw extruder is a vital machine used in various manufacturing processes. It consists of a single rotating screw housed within a heated barrel. As the screw turns, it conveys, compresses, and melts materials, allowing for continuous shaping and forming.

● Screw: The primary component responsible for material movement and processing.

● Barrel: Houses the screw and provides heating zones to melt materials.

● Drive Motor: Powers the screw rotation, enabling material processing.

● Die: Shapes the final product as the melted material exits the extruder.

Unlike twin screw extruders, which feature two intermeshing screws, single screw extruders are simpler and easier to operate. The single screw design reduces complexity, making it ideal for straightforward applications where consistent output is required.

Single screw extruders find extensive use in various industries due to their versatility. Here are some key sectors where they play a crucial role:

Industry | Typical Applications | Products Produced |

Plastics | Film extrusion, pipe production | Plastic sheets, tubes, and profiles |

Food Processing | Snack production, pet food manufacturing | Breakfast cereals, dry kibble |

Rubber | Rubber compounding, tire manufacturing | Rubber sheets, seals, and gaskets |

In the plastics industry, single screw extruders are essential for producing a wide range of products, from packaging films to pipes. They efficiently process thermoplastics, ensuring a uniform melt flow that meets quality standards.

In food processing, these machines excel at creating snacks and pet food. The ability to control temperature and pressure allows for consistent product quality and texture. Single screw extruders facilitate the production of various food items, adapting easily to different formulations.

Rubber processing also benefits from single screw extruders, which ensure uniform mixing and precise control over material properties. This adaptability makes them a popular choice for manufacturers looking to streamline production while maintaining high standards.

Overall, single screw extruders are indispensable in many sectors, providing reliable performance and cost-effectiveness. Their ability to handle diverse materials while producing high-quality products makes them a preferred option for manufacturers worldwide.

Single screw extruders are renowned for their straightforward design, which significantly contributes to their cost-effectiveness. Unlike twin screw extruders, which feature complex intermeshing screws, single screw extruders have fewer moving parts. This simplicity not only reduces the initial manufacturing costs but also minimizes ongoing operational expenses.

The design allows for easier assembly and disassembly, which simplifies maintenance tasks. As a result, facilities can save on both labor costs and downtime associated with repairs.

Feature | Single Screw Extruder | Twin Screw Extruder |

Initial Cost | Lower | Higher |

Maintenance Cost | Lower | Higher |

Complexity of Operation | Simple | Complex |

This table highlights how the single screw extruder stands out in terms of affordability, making it an attractive option for manufacturers looking to optimize their budgets.

One of the standout features of single screw extruders is their remarkable ability to process a wide range of materials. They can efficiently handle various types of plastics, rubber, and food products, making them incredibly versatile. This adaptability is crucial in today’s fast-paced manufacturing environment, where the ability to switch between different materials can lead to significant time and cost savings.

● Plastics: Single screw extruders are particularly effective for thermoplastics, ensuring a consistent melt flow that meets stringent quality standards. They can produce everything from plastic sheets to intricate molded parts.

● Rubber: In the rubber industry, these extruders excel at compounding and mixing rubber materials, ensuring uniformity and quality in the final product. This capability is vital for producing items like tires and seals.

● Food Products: The food processing sector benefits greatly from single screw extruders, which can adapt to produce a variety of snacks and cereals. The precise control over temperature and pressure allows for the creation of products with desirable textures and flavors.

This versatility allows manufacturers to easily switch between different materials and applications, catering to diverse production requirements and market demands.

Energy consumption is a critical factor in manufacturing, especially as companies strive to reduce their carbon footprint and operational costs. Single screw extruders are designed to be energy-efficient, consuming less power compared to their twin screw counterparts. This efficiency not only helps in lowering operational costs but also minimizes the environmental impact of production.

● Lower Power Usage: By utilizing streamlined designs and optimized processing conditions, single screw extruders operate efficiently, requiring less energy to achieve the same output as more complex machines.

● Cost Savings: The reduction in energy bills leads to significant savings over time, allowing manufacturers to allocate resources more effectively. This energy efficiency can also enhance the sustainability profile of a company, appealing to environmentally conscious consumers.

In large-scale operations, throughput is a vital metric that directly impacts productivity and profitability. Single screw extruders excel in producing high volumes of material quickly and efficiently. Their design allows for continuous operation, making them ideal for high-demand environments where time is of the essence.

● Production Capacity: These machines are capable of processing large quantities of material in a short period, which is essential for meeting tight production schedules.

● Efficiency: High throughput rates ensure timely delivery of products, reducing lead times and allowing manufacturers to respond swiftly to customer demands. This capability is particularly beneficial in industries where speed and reliability are critical.

Single screw extruders feature user-friendly designs that simplify operation and maintenance. Operators can quickly learn to use these machines, which reduces training time and associated costs. The intuitive controls and straightforward layout make it easy for personnel to manage operations effectively.

● User-Friendly Design: The simplicity of the machine’s design means that operators can focus on production rather than troubleshooting complex systems. This ease of use enhances overall productivity.

● Maintenance Advantages: Fewer components mean less frequent repairs and maintenance are required. This advantage is crucial for minimizing downtime, ensuring that production lines run smoothly and efficiently.

Uniformity is essential in production, especially in industries where product quality is paramount. Single screw extruders provide consistent output quality, ensuring that each batch meets the required standards. This reliability is vital for maintaining customer satisfaction and trust.

● Importance of Uniformity: Consistent results build trust with customers and help manufacturers maintain their reputations in competitive markets.

● Achieving Consistency: Controlled processing conditions, such as temperature and pressure, contribute to uniform quality. This ability to produce reliable products over time is a significant advantage for manufacturers.

Flexibility is a key advantage of single screw extruders. They can easily scale production up or down based on market demands. This adaptability allows manufacturers to respond quickly to changes in order volumes without significant investment in new equipment.

● Production Scaling: The design of single screw extruders enables manufacturers to adjust output levels to meet varying demand, making it easier to manage production schedules.

● Market Responsiveness: Quick adaptation to fluctuations in the market ensures that manufacturers can seize opportunities and maintain competitiveness. This scalability is particularly valuable in industries characterized by rapid changes in consumer preferences.

Single screw extruders have a long history of successful applications across various industries. Their reliability has been demonstrated through numerous case studies, showcasing their effectiveness in different settings.

● Historical Reliability: These machines have been used for decades, proving their worth in manufacturing processes. Many companies have relied on single screw extruders to maintain high standards of production.

● Successful Implementations: Examples of businesses benefiting from this technology can be found in sectors ranging from plastics to food processing. These success stories highlight the versatility and effectiveness of single screw extruders in real-world applications.

Manufacturers can customize single screw extruders to meet specific production needs. This flexibility allows for tailored solutions that address unique industry challenges.

● Tailoring Equipment: Adjusting designs to fit particular applications ensures optimal performance. Customization can include modifications to screw design, barrel length, and heating zones.

● Industry-Specific Needs: By offering customizable options, manufacturers can ensure that their extruders meet the precise requirements of their production processes, enhancing efficiency and product quality.

With these comprehensive advantages, single screw extruders continue to be a preferred choice for manufacturers looking to enhance efficiency, reduce costs, and maintain high-quality production standards.

Single screw extruders shine in specific situations, particularly when dealing with certain materials. They are especially effective for processing thermoplastics like polyethylene and polypropylene. These materials flow easily and can be consistently melted and shaped in a single screw setup.

Material Type | Characteristics | Examples of Use |

Thermoplastics | Easy to melt and process | Packaging films, containers |

Rubber | Requires consistent mixing | Tires, seals |

Food Products | Needs careful temperature control | Snacks, pet food |

In these cases, single screw extruders provide efficient processing and high-quality output. They are less suited for materials requiring extensive mixing or complex formulations, where twin screw extruders might be more effective.

When evaluating equipment, budget is always a key factor. Single screw extruders typically have lower initial costs compared to twin screw models. This affordability makes them an attractive option for many businesses, especially startups or those with limited capital.

Feature | Single Screw Extruder | Twin Screw Extruder |

Initial Cost | Lower | Higher |

Maintenance Costs | Generally lower | Higher |

Energy Consumption | More efficient | Less efficient |

In addition to the lower purchase price, single screw extruders often result in long-term savings. Their energy efficiency and reduced maintenance needs contribute to a better return on investment (ROI) over time. Companies can allocate resources more effectively, allowing for reinvestment into other areas of the business.

High output is a critical requirement for many manufacturers. Single screw extruders excel in scenarios where consistent and rapid production is necessary. Their design allows for continuous operation, which is essential for meeting large-scale demands.

When it comes to product changeovers, single screw extruders offer flexibility. They can be adjusted quickly for different products without extensive downtime. This adaptability is vital in industries where market trends shift rapidly, and manufacturers need to respond promptly.

● Quick Changeovers: Single screw extruders can switch between materials or product types with minimal adjustments.

● Consistent Output: They maintain high throughput rates, ensuring that production targets are met without sacrificing quality.

In environments where speed and adaptability are crucial, single screw extruders provide the necessary features to keep operations running smoothly.

Recent innovations in single screw extruder design have significantly enhanced their performance. Features like grooved feed zones and barrier screws have transformed how materials are processed.

● Improved Material Feeding: Grooved feed zones increase the surface area for material entry, allowing for better feeding and reduced friction.

● Enhanced Melting Efficiency: The design promotes more uniform melting, which is crucial for achieving consistent product quality.

Barrier screws, on the other hand, help in managing the material flow more effectively. They create a barrier that prevents backflow, ensuring that the material is adequately compressed and melted before exiting the die. This innovation is particularly beneficial for processing a variety of materials, including those with different viscosities.

Modern single screw extruders now incorporate advanced control mechanisms, such as servo drives. These systems allow for precise speed and torque control, which directly impacts production quality and efficiency.

● Precision Control: Servo drives enable real-time adjustments to the screw speed, ensuring optimal processing conditions for different materials.

● Increased Efficiency: By maintaining consistent torque, these drives reduce energy consumption and enhance overall throughput.

The integration of these control systems allows manufacturers to optimize their processes, leading to higher quality outputs and reduced waste.

The compact design of modern single screw extruders facilitates easier integration into existing production systems. Their smaller footprint means they can fit into tighter spaces, making them suitable for various manufacturing environments.

Feature | Advantages |

Low Vibration Levels | Reduces wear on machinery and improves operator comfort. |

Reduced Noise Levels | Creates a more pleasant working environment, enhancing productivity. |

These design improvements not only make installation simpler but also contribute to overall operational efficiency. By minimizing vibrations and noise, manufacturers can create a more conducive atmosphere for their workforce, ultimately boosting productivity and morale.

Incorporating these advancements into production lines ensures that companies stay competitive and can adapt to changing industry demands more effectively.

Single screw extruders offer numerous advantages, including simplicity, cost-effectiveness, and versatility in material processing. Their energy efficiency and high throughput rates make them ideal for modern manufacturing needs. Companies like Jwell provide innovative solutions, ensuring consistent output quality and scalability. Businesses should consider Jwell's single screw extruders to enhance their production efficiency and meet market demands effectively.

A: A single screw extruder is a machine used to process materials like plastics and rubber by melting and shaping them through a rotating screw.

A: The advantages include cost-effectiveness, energy efficiency, and versatility in processing a wide range of materials.

A: A single screw extruder has a simpler design with one screw, while a twin screw extruder features two intermeshing screws for more complex mixing.

A: Businesses should choose a single screw extruder for its ease of operation, lower maintenance costs, and high throughput rates.

A: A single screw extruder can produce various products, including plastic sheets, food items, and rubber components.

A: Common troubleshooting steps include checking for blockages, ensuring proper temperature settings, and inspecting the screw for wear.