- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2026-01-21 Origin: Site

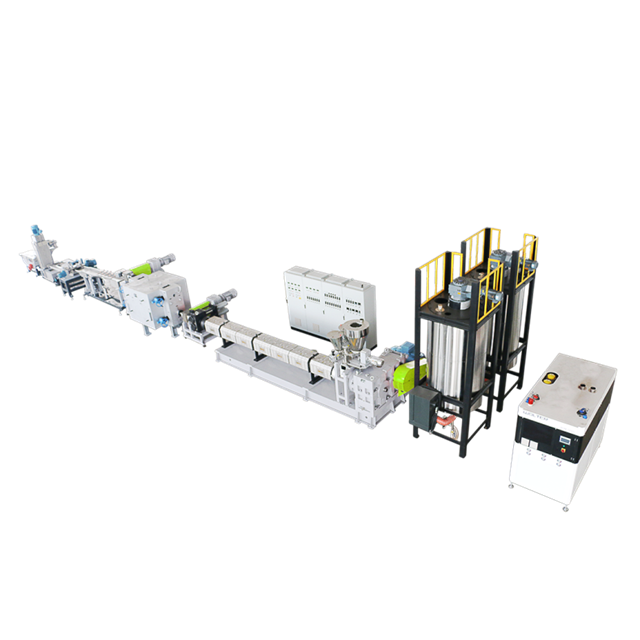

Have you ever wondered how plastic products are made? The process behind it is fascinating and crucial to modern manufacturing. A single screw extruder is a key machine in the plastic processing industry. It melts and shapes materials into various products, playing a vital role in manufacturing. In this post, you'll learn about the single screw extruder, its components, and its importance in producing high-quality plastic products.

A single screw extruder is a vital machine used in the plastic processing industry. It consists of a rotating screw housed within a heated barrel. This equipment melts, mixes, and shapes plastic materials into various products. The process begins with solid plastic pellets being fed into the hopper, where they are gradually transformed into a molten state.

The working principle is simple yet effective. As the screw rotates, it pushes the plastic forward through the barrel. The combination of heat and pressure causes the plastic to melt. This molten material is then mixed thoroughly before being forced through a die, which shapes it into the desired form.

The screw is the heart of the single screw extruder. Its design features a helical shape that plays a crucial role in the extrusion process. The screw’s geometry, including its pitch and depth, affects how efficiently it conveys and melts the plastic.

● Adjustable Parameters:Pitch: This refers to the distance between the screw threads. A larger pitch can enhance material flow.

○ Compression Ratio: This is the ratio of the feed section depth to the die depth. A higher ratio increases pressure and improves melting.

○ Flight Depth: The depth of the screw flights affects the material's movement and mixing efficiency.

Parameter | Description |

Pitch | Distance between screw threads |

Compression Ratio | Ratio of feed section depth to die depth |

Flight Depth | Depth of the screw flights |

The barrel houses the screw and provides the necessary environment for melting the plastic. It features multiple heating zones that ensure uniform temperature distribution.

● Heating Mechanisms: Electric heaters are commonly used to maintain the desired temperature. This is crucial for effective melting.

● Importance of Design: A well-designed barrel allows for efficient heat transfer and material flow.

● Cooling Zones: After the material exits the die, cooling zones help solidify the extrudate quickly.

The die is a critical component that shapes the molten plastic into specific forms. Different die designs can produce various profiles, such as sheets, pipes, or films.

● Shaping the Extrudate: The die determines the final shape of the product, making it essential for meeting specifications.

● Cooling Systems: Once the plastic exits the die, it must be cooled rapidly to maintain its shape. Cooling can be achieved through air or water baths.

Die Type | Application |

Flat Die | Producing sheets |

Round Die | Creating pipes |

Custom Die | Specialized shapes for unique products |

In summary, understanding the single screw extruder involves exploring its definition, functionality, and key components. Each part plays a significant role in ensuring the efficient production of high-quality plastic products.

The extrusion process is a fascinating journey that transforms raw plastic into finished products. It begins when plastic pellets are loaded into the hopper of the single screw extruder. From there, the screw rotates, pushing the material forward through the barrel. As the plastic moves, it encounters various heating zones that raise its temperature, causing it to melt.

● Step-by-Step Breakdown:Material Loading: Solid plastic pellets are introduced into the hopper.

○ Melting Phase: The rotating screw applies shear and pressure, melting the plastic as it moves through the barrel.

○ Mixing Phase: The molten plastic is mixed thoroughly, ensuring uniformity.

○ Shaping Phase: The melted plastic is forced through a die, giving it the desired shape.

○ Cooling and Finishing: After exiting the die, the plastic is cooled quickly to solidify its shape.

Temperature control is crucial throughout this process. Maintaining the right temperature ensures that the plastic melts evenly and prevents degradation. Pressure management also plays a role, as it helps maintain the flow of material through the extruder.

Phase | Description |

Material Loading | Pellets enter the hopper |

Melting Phase | Heat and pressure melt the plastic |

Mixing Phase | Ensures uniformity of the molten plastic |

Shaping Phase | Plastic is formed into desired shapes |

Cooling and Finishing | Rapid cooling solidifies the extrudate |

Shear and friction are key players in this process. As the screw rotates, it generates heat through friction, aiding in the melting of the plastic. This mechanical energy is vital for achieving the right viscosity for extrusion.

Several factors can significantly impact the performance of a single screw extruder. Understanding these elements helps optimize the extrusion process for various applications.

The speed of the screw is a critical factor in determining how effectively the extruder operates.

● Effects on Melting and Mixing: Higher screw speeds can enhance the melting and mixing of materials. However, too high a speed may lead to excessive shear, causing degradation.

● Optimal Speeds: Different materials require different screw speeds for optimal performance. For instance, softer thermoplastics may melt efficiently at lower speeds, while harder materials may need faster rotations.

● Energy Consumption: The relationship between screw speed and energy consumption is essential. Higher speeds can increase energy use, so finding a balance is key to efficiency.

Material Type | Optimal Screw Speed (RPM) |

Polyethylene (PE) | 50-100 |

Polypropylene (PP) | 70-120 |

Polystyrene (PS) | 40-90 |

The types of materials used in single screw extrusion greatly influence the overall process.

● Suitable Materials: Common materials include polyethylene (PE), polypropylene (PP), and polystyrene (PS). Each has unique properties that affect melting and flow.

● Material Characteristics: Factors such as viscosity, melting temperature, and thermal stability are crucial. These characteristics determine how well a material can be processed.

● Thermoplastics: Thermoplastics are particularly relevant, as they soften when heated and solidify upon cooling. This property makes them ideal for the extrusion process.

Understanding these factors allows manufacturers to optimize their processes, ensuring high-quality outputs and efficient production. By carefully managing screw speed and selecting the right materials, the performance of a single screw extruder can be enhanced significantly.

One of the most compelling reasons to choose a single screw extruder is its cost-effectiveness. Compared to twin screw extruders, single screw models typically have lower design and operational costs. This is largely due to their simpler construction and fewer components.

● Design and Operation Costs: Twin screw extruders often require more complex machinery and additional parts, leading to higher initial investments. In contrast, single screw extruders are easier to manufacture and maintain.

● Operational and Maintenance Overhead: The maintenance costs for single screw extruders are generally lower. Fewer moving parts mean less wear and tear, which translates to less frequent repairs and downtime. This makes them an attractive option for businesses looking to maximize their return on investment.

Cost Aspect | Single Screw Extruder | Twin Screw Extruder |

Initial Investment | Lower | Higher |

Maintenance Costs | Lower | Higher |

Complexity | Simpler | More Complex |

Single screw extruders are renowned for their versatility. They can produce a wide range of products, making them suitable for various industries.

● Types of Products: These machines can create pipes, sheets, films, and profiles. Each product type has unique requirements, and single screw extruders can adapt to meet these needs.

● Industry Applications: The applications are vast. In the construction industry, they create pipes for plumbing and drainage. In automotive manufacturing, they produce components like dashboards and interior panels. Packaging industries also benefit from single screw extruders, producing flexible films and containers.

Product Type | Industry Application |

Pipes | Construction |

Sheets | Packaging |

Films | Food Packaging |

Profiles | Automotive |

The quality of products produced by single screw extruders is another significant advantage. Consistency and precision are critical in manufacturing, and single screw extruders excel in this area.

● Consistency and Quality: They produce uniform extrudates, ensuring that each product meets the required specifications. This consistency is vital for applications where dimensional accuracy is crucial.

● Importance of Design: The design of the screw and barrel significantly influences the quality of the output. A well-designed screw can enhance mixing and melting, leading to better product quality.

● Examples of High-Quality Applications: Industries such as food packaging and medical supplies require high-quality extrudates. Single screw extruders can meet these stringent standards, providing reliable and durable products.

Quality Aspect | Benefits |

Consistency | Uniform products |

Design Influence | Enhanced mixing |

Application Examples | Food and medical |

In summary, the advantages of using a single screw extruder extend beyond cost savings. Their versatility and ability to produce high-quality products make them a preferred choice across various industries.

When comparing single screw extruders to twin screw extruders, several key differences emerge, particularly in functionality and applications.

● Functionality: Single screw extruders utilize one screw to convey, melt, and shape materials. This simplicity makes them easier to operate and maintain. On the other hand, twin screw extruders feature two intermeshing screws that provide enhanced mixing capabilities. This design is ideal for producing highly homogeneous blends.

● Applications: Single screw extruders are often used for producing profiles, sheets, and pipes, where consistent output is essential. Conversely, twin screw extruders are preferred for applications requiring precise mixing, such as compounding and processing materials with additives.

Feature | Single Screw Extruder | Twin Screw Extruder |

Number of Screws | One | Two |

Mixing Capability | Moderate | High |

Complexity | Simpler design | More complex |

Maintenance | Easier and less frequent | Requires more upkeep |

Both types of extruders have their advantages and disadvantages.

● Single Screw Extruder:

○ Pros: Cost-effective, simpler design, lower maintenance.

○ Cons: Limited mixing capability, not ideal for materials requiring precise blending.

● Twin Screw Extruder:

○ Pros: Excellent mixing, suitable for a wide range of materials, including those with additives.

○ Cons: Higher initial cost, more complex operation, and maintenance.

Selecting the right extruder depends on various factors. Understanding your specific needs can guide this decision.

● Factors to Consider:

○ Production Volume: High-volume production often benefits from the efficiency of single screw extruders. However, if your product requires complex formulations, a twin screw extruder may be necessary.

○ Material Types: Some materials, especially those needing additives or fillers, perform better in twin screw extruders due to their superior mixing capabilities.

● Application-Specific Recommendations:

○ For simple products like pipes and sheets, a single screw extruder is typically sufficient.

○ If you are working on specialized products, such as those in the food or pharmaceutical industries, the precision of a twin screw extruder would be more beneficial.

Application Type | Recommended Extruder |

Pipes and Sheets | Single Screw Extruder |

Compounding and Mixing | Twin Screw Extruder |

Specialized Blends | Twin Screw Extruder |

By considering your production needs and the characteristics of the materials involved, you can make an informed decision on whether a single screw or twin screw extruder is the best fit for your operations.

The world of single screw extrusion is evolving rapidly, driven by recent technological advances that enhance performance and efficiency. Innovations in screw design have played a crucial role in optimizing the extrusion process. New screw geometries and configurations improve material flow and mixing, resulting in higher-quality extrudates.

● Heating and Cooling Systems: Modern single screw extruders now feature advanced heating and cooling systems that ensure precise temperature control. This is vital for maintaining consistent material properties throughout the extrusion process. Improved thermal management helps reduce energy consumption and minimizes the risk of material degradation.

● Automation and Control Systems: Automation has transformed the extrusion industry. Advanced control systems enable real-time monitoring and adjustments, enhancing extrusion efficiency. These systems can optimize parameters such as temperature, pressure, and screw speed, leading to better product quality and reduced waste.

● Durability Enhancements: The use of advanced materials and coatings for screws is another significant innovation. These enhancements increase the durability of screws, reducing wear and extending their lifespan. Coatings like nitride or ceramic can also improve resistance to corrosion and abrasion, making them ideal for processing challenging materials.

Innovation Type | Description |

Screw Design | New geometries for improved flow and mixing |

Heating/Cooling Systems | Enhanced thermal control for consistent output |

Automation | Real-time monitoring for optimal performance |

Durability Coatings | Advanced materials to extend screw lifespan |

Looking ahead, the future of single screw extruders is promising, with several key trends expected to shape their development.

● Predictions for Advancements: Future advancements may include even more sophisticated screw designs that adapt to various materials and production requirements. We can anticipate the integration of artificial intelligence to predict and adjust processing conditions, further enhancing efficiency and product quality.

● Sustainability and Energy Efficiency: As industries increasingly focus on sustainability, future designs of single screw extruders will prioritize energy efficiency. Innovations aimed at reducing energy consumption during the extrusion process will not only lower operational costs but also minimize environmental impact.

● New Applications and Markets: The versatility of single screw extruders opens doors to potential new applications and markets. Industries such as bioplastics and advanced composites are emerging areas where single screw technology could play a crucial role. As these markets grow, the demand for adaptable and efficient extrusion solutions will rise.

Future Trend | Potential Impact |

Advanced Screw Designs | Improved adaptability for various materials |

AI Integration | Enhanced process optimization |

Energy Efficiency | Reduced operational costs and environmental impact |

New Market Applications | Expansion into bioplastics and advanced composites |

These innovations and trends indicate a vibrant future for single screw extruders, positioning them as essential tools in modern manufacturing. As technology continues to evolve, these machines will play a pivotal role in meeting the demands of diverse industries.

Single screw extruders are essential in plastic processing. They offer a cost-effective solution for various manufacturing needs. Their simplicity and versatility make them suitable for producing pipes, sheets, and films. Companies like Jwell provide innovative extruders that enhance efficiency and product quality. Their products feature advanced designs and automation, ensuring high performance. We encourage readers to explore single screw extrusion and share their experiences or questions. Follow our blog for more insights into plastic processing technologies.

A: A single screw extruder is a machine used for processing thermoplastics. It uses one screw to melt, mix, and shape materials into various products.

A: The single screw extruder works by feeding plastic pellets into a heated barrel. The rotating screw melts the material and pushes it through a die to form desired shapes.

A: A single screw extruder is often more cost-effective and easier to maintain. It is ideal for applications that require consistent output without complex mixing.

A: The advantages include lower operational costs, simplicity in design, and versatility in producing various products like pipes and sheets.

A: Factors include screw design, material type, temperature control, and processing speed, all of which impact the efficiency and quality of the output.