- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

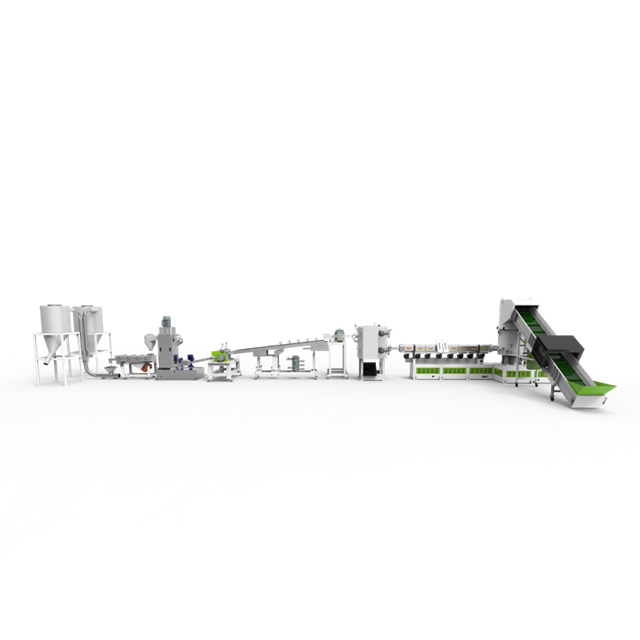

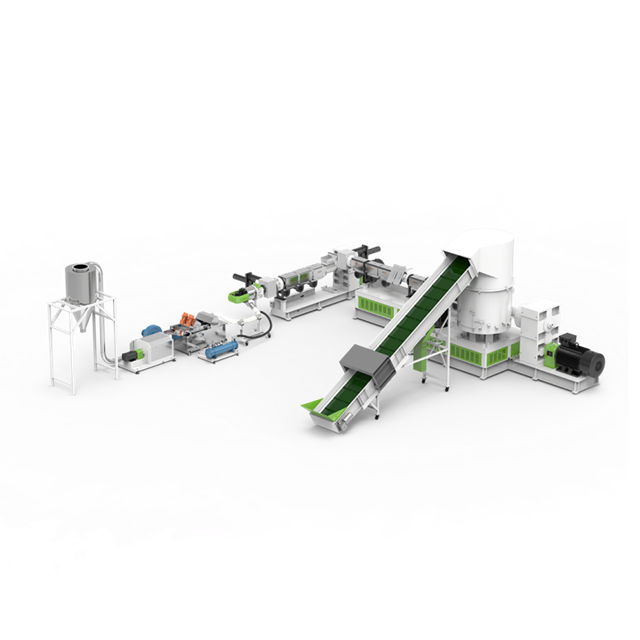

Did you know that the plastic industry contributes significantly to environmental pollution? PLA, a plant-based plastic, offers a more sustainable alternative. However, recycling PLA effectively is crucial to minimize its environmental impact. In this post, you'll learn about PLA's composition, its environmental benefits, and the importance of recycling. We'll explore various PLA recycling processes, including mechanical and chemical methods, to support sustainable practices. Advanced plastic pelletizing machine, high-performance plastic crusher machine - Dyun plays a crucial role in the mechanical recycling process, transforming PLA waste into reusable pellets efficiently."

PLA, or polylactic acid, is a bioplastic made mostly from renewable plant sources like corn starch, sugarcane, or cassava. It starts as starch, which is broken down into sugars and fermented to produce lactic acid. This lactic acid then polymerizes into long chains forming PLA. Unlike traditional plastics derived from petroleum, PLA's plant-based origin makes it more sustainable. Its chemical structure is a polyester, which gives it thermoplastic properties—meaning it softens when heated and hardens when cooled, allowing for recycling and reshaping.

One of PLA's biggest advantages is its ability to biodegrade under specific conditions. It breaks down into water, carbon dioxide, and biomass when exposed to industrial composting environments with high heat (around 60°C) and controlled humidity. However, PLA does not degrade quickly in regular landfills or home compost setups because these conditions lack the necessary heat and microbes. This means PLA is compostable but only in industrial facilities designed for this purpose. In natural environments or typical trash bins, PLA behaves more like regular plastic and can persist for years.

Compared to conventional plastics like ABS, PET, or polystyrene, PLA offers several distinct benefits:

● Source Material: PLA comes from renewable plants, whereas traditional plastics rely on fossil fuels.

● Environmental Impact: Producing PLA consumes less energy and emits fewer greenhouse gases.

● Biodegradability: PLA can break down under industrial composting, while most traditional plastics do not degrade naturally.

● Toxicity: When burned, PLA degrades into non-toxic lactic acid, unlike some plastics that release harmful chemicals.

● Physical Properties: PLA is water-resistant, moldable, and fairly strong but has a lower melting point (about 150–160°C) and is more brittle. This limits its use in high-heat or heavy-load applications.

While PLA offers a greener alternative, it’s important to note its limitations. It is less heat resistant and more prone to cracking, so it may not replace all traditional plastics in every application. Still, its renewable origin and compostability make it a popular choice for 3D printing, packaging, and other uses aiming to reduce environmental impact.

PLA requires industrial composting facilities to biodegrade effectively; home composting or landfill disposal significantly slows its breakdown.

Mechanical recycling of PLA starts by breaking down waste into smaller pieces. This begins with shredding PLA prints, failed attempts, or scraps into flakes or pellets. Shredding makes it easier to handle and process the material in the next steps. A granulator or shredder designed for plastics is ideal for this task, ensuring uniform particle size. Before shredding, it’s important to sort PLA from other plastics to avoid contamination, which can degrade the quality of recycled filament.

After shredding, the PLA particles often need cleaning to remove dust, oils, or residues. Washing and drying the shredded PLA help improve the quality of recycled filament. Moisture is a concern because PLA absorbs water, which can cause bubbles or weak spots during melting. Drying shredded PLA at around 50–60°C for a couple of hours reduces moisture content, making extrusion smoother.

Once shredded and dried, PLA is ready for re-extrusion. This involves melting the flakes and pushing them through a nozzle to form new filament. The extrusion temperature typically ranges from 180°C to 200°C, carefully controlled to avoid overheating, which can degrade the polymer.

During extrusion, the molten PLA is shaped into a continuous strand and cooled quickly to retain its round shape. It’s then wound onto spools for use in 3D printing. Consistent filament diameter is essential for good print quality, so extrusion machines often include diameter sensors and feedback controls.

Re-extrusion allows companies or hobbyists to turn wasted PLA into usable filament, cutting material costs and reducing plastic waste. However, each recycling cycle can slightly degrade PLA’s properties, so mixing recycled PLA with some virgin material often produces the best results.

Mechanical recycling faces several challenges:

● Thermal Degradation: Repeated heating causes PLA chains to break down, reducing strength and flexibility.

● Contamination: Mixing PLA with other plastics or impurities lowers filament quality and can cause print failures.

● Moisture Sensitivity: PLA absorbs water, which leads to bubbles or weak spots during extrusion.

● Color Mixing: Recycling PLA of different colors results in mixed or dull filament colors, limiting aesthetic options.

To overcome these issues, businesses can:

● Use dedicated sorting to keep PLA pure.

● Dry shredded PLA thoroughly before extrusion.

● Blend recycled PLA with virgin pellets to restore material properties.

● Implement quality control checks during extrusion for consistent filament diameter.

● Separate PLA colors before recycling if color consistency is important.

Investing in specialized shredders and professional-grade filament extruders improves the recycling process. These machines provide better control over particle size, temperature, and filament quality. Additionally, regular maintenance of equipment helps prevent contamination and ensures smooth operation.

Mechanical recycling of PLA offers a practical way to reduce waste and reuse material. Though it may not fully restore PLA to virgin quality, it supports sustainability and cost savings, especially when combined with proper sorting and drying practices.

Always dry shredded PLA thoroughly before extrusion to prevent moisture-related defects and improve recycled filament quality.

Chemical recycling breaks down PLA into its original building blocks or other useful chemicals. Unlike mechanical recycling, which melts and reshapes plastic, chemical recycling uses chemical reactions to depolymerize PLA. This process can handle PLA waste contaminated or mixed with other materials, producing high-purity outputs. It offers a way to recycle PLA that might be unsuitable for mechanical recycling due to impurities or degradation.

Several chemical recycling methods exist for PLA, each using different chemicals and conditions:

● Hydrolysis: This process uses water, often heated under pressure, to break PLA chains into lactic acid monomers. Hydrolysis can occur under acidic, neutral, or basic conditions. The lactic acid produced can be purified and repolymerized into virgin PLA or used in other applications. Hydrolysis is relatively straightforward but can require high temperatures and pressure.

● Methanolysis: In methanolysis, PLA reacts with methanol under heat, breaking down into methyl lactate. This intermediate can be further processed to recover lactic acid or converted into other chemicals. Methanolysis often requires catalysts to speed up the reaction and optimize yields.

● Glycolysis: This method uses glycols (like ethylene glycol) to depolymerize PLA into oligomers or monomers. Glycolysis is common in recycling polyesters and can produce valuable intermediates for chemical manufacturing.

Each process involves controlled reaction conditions to maximize recovery and minimize byproducts. The choice depends on the desired output, available infrastructure, and economic considerations.

Advantages:

● Can recycle PLA contaminated or unsuitable for mechanical recycling.

● Produces high-purity lactic acid or intermediates, allowing for virgin-quality PLA production.

● Helps close the loop in PLA’s lifecycle by enabling multiple recycling cycles without significant degradation.

● Enables recovery of monomers useful for other chemical industries.

Disadvantages:

● Typically more energy-intensive than mechanical recycling due to heating and chemical use.

● Requires specialized equipment and chemical handling expertise.

● May involve hazardous chemicals or generate waste streams needing treatment.

● Currently less accessible for small-scale or home-based operations.

● Economic viability depends on scale and market demand for recovered chemicals.

Chemical recycling offers a promising complement to mechanical recycling, especially for dealing with PLA waste that mechanical methods cannot handle well. It supports a circular economy by turning PLA back into raw materials, reducing reliance on new feedstocks.

When considering chemical recycling for PLA, evaluate the availability of local facilities and the economic feasibility before investing in specialized equipment or processes.

Professional-grade filament extruders provide clear advantages for recycling PLA at scale. They offer precise control over temperature, extrusion speed, and filament diameter, which helps produce consistent, high-quality filament. This level of control reduces filament defects like uneven thickness or brittleness, essential for reliable 3D printing.

Using such extruders also simplifies the recycling process. Instead of relying on trial and error, users can set optimized parameters for different PLA batches. This reduces material waste and downtime. Moreover, many professional extruders come with integrated drying systems or moisture control, tackling PLA’s sensitivity to water.

Environmental benefits are significant too. Recycling PLA waste onsite with an industrial extruder cuts down on transportation emissions and packaging waste. It supports a circular economy by turning scrap prints and failed attempts back into usable filament. This reduces demand for virgin PLA, lowering the overall carbon footprint.

Investing in industrial filament extrusion can save money long term. By recycling your own PLA waste, you reduce the need to buy new filament, which can be costly. Over time, these savings add up, especially for businesses or institutions producing large volumes of 3D prints.

Scalability is another key benefit. Professional extruders are designed to handle larger batches, making them suitable for growing operations. Some systems allow users to expand capacity by linking multiple extruders, creating a filament extrusion farm. This flexibility means you can start small, then scale up as demand increases.

Additionally, industrial extruders often have automated features like diameter monitoring and spool winding. These reduce labor costs and improve efficiency. Some models also support quick changeovers between filament colors or types, adding versatility.

Several organizations have successfully implemented industrial filament extrusion to recycle PLA waste and boost sustainability.

● Educational Institutions: Fontys University of Applied Sciences integrated professional extruders into their curriculum. Students learn polymer extrusion hands-on while the school recycles PLA scraps from projects. This approach reduces material costs and waste, making education more sustainable.

● Automotive Industry: Audi uses a complete recycling setup, including shredders, dryers, and industrial filament extruders. They recycle PLA waste into 3D-printed tools and parts, supporting their net-zero emissions goal. This system demonstrates how large manufacturers can adopt circular practices effectively.

● Small Businesses: Some 3D printing service providers recycle failed prints and support material onsite. Using professional extruders, they create custom filament blends, reducing costs and appealing to eco-conscious clients.

These examples show industrial filament extrusion is practical, economical, and scalable. It empowers organizations to close the loop on PLA waste, turning it into valuable resources.

When choosing a professional filament extruder, prioritize machines with integrated drying and diameter control to ensure consistent, high-quality recycled PLA filament.

One of the best ways to reduce PLA waste starts before printing—during the design phase. Thoughtful 3D model design can cut down on the amount of support material and infill needed. Use software tools to optimize your models by:

● Reducing overhangs that require supports

● Designing hollow structures instead of solid ones

● Using minimal infill percentages for non-structural parts

● Splitting large models into smaller, printable sections

These strategies help save filament and reduce failed prints caused by excessive supports or complex geometries. Less waste means less need for recycling or disposal.

Failed prints often happen because the first layer doesn’t stick well to the print bed. This leads to warping, shifting, or complete detachment during printing, wasting filament. To improve bed adhesion:

● Level your print bed regularly to keep it flat

● Use the right bed surface or adhesive (glue stick, painter’s tape, PEI sheets)

● Adjust the nozzle height to be close enough for good contact but not too close

● Control bed temperature according to filament specs (usually around 50–60°C for PLA)

Good adhesion prevents print failures and reduces scrap material, saving time and filament.

Keeping your 3D printer in top shape helps avoid common issues that cause waste. Regular maintenance includes:

● Cleaning the nozzle to prevent clogs and uneven extrusion

● Checking filament feed mechanisms for jams or slippage

● Ensuring belts and pulleys are tight and properly aligned

● Updating firmware and calibrating steps/mm for accurate movement

A well-maintained printer prints more reliably, reducing failed prints and filament waste. It also extends the printer’s lifespan, supporting sustainability.

Regularly clean and level your print bed to improve first-layer adhesion and drastically reduce failed prints that generate PLA waste.

The future of PLA recycling is bright thanks to rapid tech improvements. Mechanical recycling machines now offer better control over temperature and moisture. This means less degradation and higher-quality recycled filament. New shredders and dryers handle PLA waste more efficiently, reducing contamination risks.

Chemical recycling is advancing too. Researchers develop catalysts and processes that lower energy needs and speed up breaking PLA back into lactic acid. These innovations could make chemical recycling more affordable and accessible for businesses.

Automation plays a big role. Smart sensors and AI optimize extrusion settings in real time, ensuring consistent filament diameter and reducing waste. These systems can detect impurities early and adjust the process, improving overall yield.

Looking ahead, several exciting innovations may transform PLA recycling:

● Enzymatic Recycling: Scientists explore enzymes that can break down PLA at lower temperatures, cutting energy use and costs.

● Closed-Loop Systems: Facilities may recycle PLA scraps onsite, turning waste directly into new filament without shipping or delays.

● Hybrid Recycling: Combining mechanical and chemical methods could maximize recovery and quality, handling mixed or contaminated PLA better.

● Color Sorting Tech: Advanced optical sorting can separate PLA by color before recycling, producing vibrant recycled filament without mixing hues.

● Biodegradable Additives: New PLA blends may include additives that boost recyclability or speed up composting, improving end-of-life options.

Such innovations will make PLA recycling more efficient, cost-effective, and environmentally friendly.

PLA plays a key role in greener manufacturing and 3D printing. Its renewable origin reduces reliance on fossil fuels. Recycling PLA lowers waste and cuts emissions compared to producing virgin plastic.

As recycling tech improves, PLA’s lifecycle will close further, supporting circular economies. Businesses can reduce material costs and environmental impact by reusing PLA waste onsite or through specialized facilities.

PLA’s compostability also offers an alternative disposal route, especially where industrial composting is available. This dual option—recycling or composting—makes PLA a versatile material for sustainable practices.

In the future, PLA may become the standard for eco-conscious 3D printing and packaging. Its continued development and efficient recycling will help industries meet sustainability goals and reduce plastic pollution.

Invest in emerging recycling technologies like enzymatic or hybrid methods to future-proof your PLA recycling efforts and boost sustainability.

PLA recycling is crucial for sustainability, offering environmental benefits over traditional plastics. Encouraging sustainable 3D printing practices helps reduce waste and emissions, making PLA a preferred choice. The future of PLA recycling looks promising with technological advancements enhancing efficiency and cost-effectiveness. Changzhou Dyun Environmental Technology Co., Ltd. provides innovative solutions that add value by supporting eco-friendly manufacturing goals, fostering a circular economy, and reducing reliance on fossil fuels. Investing in PLA recycling technologies ensures a greener future for industries and the environment.

A: A Plastic rigid pelletizing machine is used to process shredded PLA into uniform pellets, which can be re-extruded into new filament, aiding in recycling.

A: It improves the efficiency of recycling by creating consistent pellets, ensuring high-quality filament production and reducing waste.

A: It prevents contamination and degradation, maintaining the quality of recycled PLA filament for reliable 3D printing.

A: Yes, it can process mixed PLA, but sorting before use ensures higher quality and reduces impurities.

A: Challenges include managing moisture sensitivity and ensuring proper maintenance for optimal performance.