- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 156 Author: Site Editor Publish Time: 2025-08-06 Origin: Site

Plastic waste is one of the most pressing environmental issues today. How can we effectively reduce its impact? Plastic shredders are key to turning waste into valuable resources.

In this article, we’ll explore how plastic shredders work, their applications, and the advantages they offer to businesses and the environment. You'll learn how these machines support recycling efforts and contribute to sustainable practices.

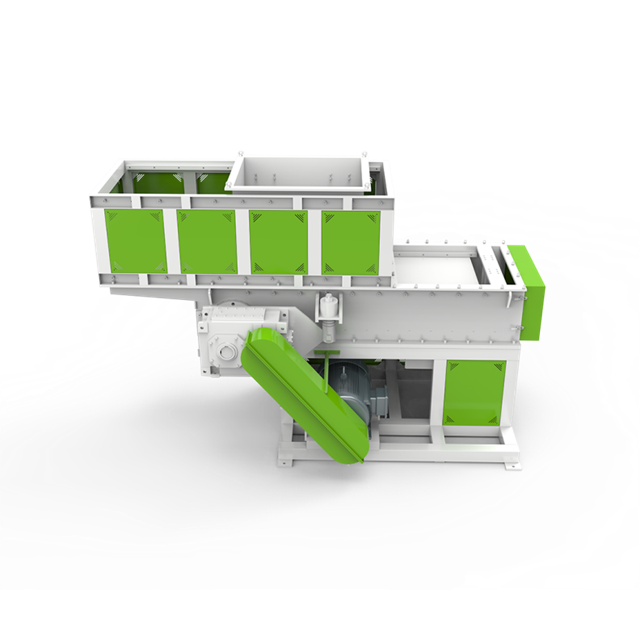

A plastic shredder is a machine designed to break down large plastic items into smaller, manageable pieces. It uses rotating blades or rotors to slice, tear, or crush plastic materials. This process is essential in the recycling industry, as it transforms plastic waste into reusable raw materials.

Plastic shredders make recycling easier by reducing the size of plastic waste, making it more convenient for processing and recycling into new products. Without shredding, handling large plastic items like bottles, containers, and films would be more difficult.

There are different types of plastic shredders, each suited for specific needs:

Single-Shaft Shredders: These shredders use one rotor to shred plastic into small, uniform pieces. They’re perfect for materials like films and bottles.

Two-Shaft Shredders: These feature two rotating shafts that shred tougher materials. They’re ideal for heavy-duty plastics like pallets or thick pipes.

Granulators: Designed to turn larger plastic items into granules or smaller particles, making it easier to reuse the material.

Mobile Shredders: Mounted on trucks or trailers, these shredders offer the flexibility to shred plastic on-site, reducing transportation costs.

Plastic shredders follow a straightforward process to break down large plastic materials. The process starts with feeding the plastic into the shredder’s hopper. From there, it moves into the shredder chamber, where the shredding occurs. The plastic is cut, torn, or crushed by rotating blades. Finally, the shredded material is discharged through a screen or chute for easy collection.

The efficiency of this process depends heavily on the blade configuration. Shredders use different blade designs, such as single, double, or multi-shaft systems, to optimize performance for various types of plastic. Blades are often made from durable materials like tool steel or alloy to withstand the rigors of constant use.

The speed of the shredding process also plays a crucial role. Faster speeds result in quicker shredding but may generate more heat, which can affect the material being processed. Slower speeds allow for more controlled shredding, ensuring uniformity in size while preventing overheating.

The combination of blade types and speed ensures that the shredder operates efficiently, depending on the material and desired output size.

Plastic shredders are pivotal in recycling, transforming large plastic items like bottles and containers into smaller, manageable pieces. This process makes it easier to reuse plastic in the creation of new products. Shredding plastic waste ensures that valuable resources don’t end up in landfills and can be repurposed instead.

Several industries benefit from this recycling process. Packaging companies often use shredded plastic to produce new containers or packaging materials. Electronics manufacturers recycle plastic parts from old devices to create new products, reducing production costs. By shredding plastic waste, these industries not only conserve raw materials but also contribute to a more sustainable production process.

The environmental benefits of plastic shredding are significant. Shredding reduces the amount of plastic waste in landfills, thus alleviating some of the strain on waste management systems. Plastic waste takes hundreds of years to decompose, contributing to pollution. By shredding and recycling plastic, we help to minimize landfill usage and reduce the volume of non-biodegradable materials in the environment.

Furthermore, plastic shredding plays a key role in the circular economy, where materials are continuously reused rather than disposed of. This practice helps reduce waste and encourages the sustainable use of resources. Shredded plastic can be transformed into new products, meaning fewer new raw materials are needed, lowering the carbon footprint associated with plastic production.

Plastic shredders are not limited to the recycling sector. They are widely used across various industrial applications, making them an essential tool in many industries.

In manufacturing, plastic shredders process scrap plastic from production lines. These machines break down plastic waste so it can be reused to produce new products, reducing waste and production costs. Similarly, the pharmaceutical industry uses shredders to securely dispose of plastic containers and packaging, ensuring they are properly recycled.

The food processing industry also benefits from plastic shredders. Packaging waste from food products, such as plastic bottles and containers, can be shredded and recycled. This reduces the environmental impact of food packaging and helps companies move towards more sustainable practices.

Other industries, such as automotive manufacturing and construction, also use plastic shredders to handle plastic waste. For example, in the automotive industry, plastic parts from old vehicles can be shredded and reused in the production of new vehicle components.

Plastic shredders are crucial for efficient waste management in these industries, contributing to a cleaner environment and lower operational costs. With a wide range of applications, these machines play a key role in modern recycling and manufacturing processes.

Plastic shredders are equipped with various blade configurations, each suited to specific types of plastic and recycling needs. The most common configurations are single, double, and multi-shaft systems.

Single-Shaft Shredders: These have one rotating shaft with sharp blades. They’re efficient for shredding soft plastics like films or bottles.

Double-Shaft Shredders: These use two rotating shafts that move in opposite directions. This setup is ideal for shredding tougher materials, such as thick plastic pipes or pallets.

Multi-Shaft Shredders: With multiple shafts, these machines are designed for high-volume, heavy-duty applications. They offer greater flexibility and durability for processing larger plastic items.

Each of these configurations impacts the shredder's efficiency and suitability for various industrial tasks.

The power of a plastic shredder is largely determined by its motor, which typically ranges from 50HP to 1,250HP. The motor's horsepower plays a crucial role in the shredder's ability to handle different types of plastic waste.

50-100HP Motors: Best for small-scale operations or lightweight plastic materials, such as plastic bottles or packaging.

100-500HP Motors: These are commonly used in mid-sized operations, processing a variety of plastics, including thicker materials like containers and films.

500-1,250HP Motors: Heavy-duty motors designed for large-scale industrial applications, capable of shredding tough plastics like automotive parts, large pipes, and thick plastic sheets.

The capacity of the shredder is directly tied to the motor power, allowing it to handle higher volumes of waste more efficiently.

One of the key advantages of modern plastic shredders is the ability to customize their features to suit specific needs. Adjustable screens are a popular option, allowing users to control the size of the shredded plastic. This ensures that the material fits the requirements of downstream processes, whether for recycling or further manufacturing.

Other customization options include:

Variable-speed motors: Allows for control over the shredding speed, which is useful for handling different plastic types.

Blade designs: Custom blades can be designed for specific materials, increasing shredding efficiency.

Feed hoppers: Custom-sized hoppers can accommodate different volumes or types of plastic waste, improving workflow and productivity.

One of the primary advantages of using plastic shredders is the cost savings they offer. Recycling plastic waste reduces the need to purchase new raw materials, which can be expensive. By shredding plastic and reusing it in production, businesses can significantly lower their operational costs.

In addition, shredders help reduce waste disposal costs. Instead of paying for plastic waste to be hauled away to landfills, companies can recycle the material. Shredding reduces the volume of waste, making it easier and cheaper to manage. This is particularly beneficial for industries that produce large amounts of plastic waste, such as manufacturing or packaging.

Plastic shredders play a key role in promoting sustainability. By shredding and recycling plastic, we help reduce the amount of plastic waste sent to landfills. Plastic waste is non-biodegradable, meaning it can stay in landfills for hundreds of years. Using shredders to recycle this waste directly contributes to environmental protection by diverting it from landfills.

Additionally, shredders support the circular economy. This system promotes the continuous reuse of materials, reducing the need for new raw materials. Recycled plastic can be used to make new products, minimizing the demand for virgin plastic and decreasing the environmental impact associated with plastic production. This helps companies lower their carbon footprint and conserve natural resources.

Plastic shredders make the recycling process more efficient by facilitating easier handling and processing of plastic waste. When plastic is shredded, it becomes much easier to handle, transport, and store. The smaller pieces are also more uniform, which improves the efficiency of sorting and further processing.

In addition, shredded plastic can be processed more quickly and effectively in recycling facilities. This helps create higher quality recycled products that can be used in manufacturing. Without shredding, plastic waste would be much harder to recycle, and the quality of the final products would suffer. By shredding plastic waste, companies can ensure that the recycled material is suitable for creating new products, making the recycling process much more effective.

Waste minimization is another significant advantage of plastic shredders. Shredding plastic waste reduces its overall volume, making it easier to store and transport. With smaller plastic pieces, businesses can save on storage space and reduce transportation costs. This also makes it easier to manage waste, as smaller quantities can be processed more quickly.

By minimizing plastic waste, companies also contribute to reducing their environmental impact. Less waste in landfills means fewer negative effects on ecosystems and communities. Additionally, businesses can repurpose shredded plastic into new products, contributing to a more sustainable approach to waste management.

Plastic shredders are also used for more than just recycling plastic materials. Many businesses use shredders to destroy confidential documents or materials. Whether it's old files, outdated hard drives, or sensitive business documents, shredding ensures privacy and security. By using a shredder, companies can protect their confidential information from being accessed by unauthorized individuals.

This feature is especially important in industries like healthcare, finance, and legal services, where the protection of private data is a priority. Shredding these materials helps prevent identity theft, corporate espionage, or data breaches. It's a simple yet effective way to ensure compliance with privacy regulations and protect your business from potential legal issues.

Using plastic shredders brings many benefits, from reducing costs and promoting sustainability to improving recycling efficiency and security. These advantages make shredders an essential tool for businesses in various industries, helping them save money, protect the environment, and ensure the safety of sensitive information.

To ensure the longevity and efficiency of a plastic shredder, regular maintenance is essential. Key components like the blades, motor, and feed systems need to be checked frequently to ensure smooth operation.

Blades: Over time, blades can become dull or damaged. Regular inspection is needed to check for wear and tear. Sharpening or replacing them when necessary ensures consistent shredding quality.

Motor: The motor should be checked for any signs of overheating or unusual noise. Routine checks on motor performance help avoid costly repairs and downtime.

Feed Systems: Keeping the feed systems clear of debris or blockages ensures smooth operation. Regular cleaning of the hopper and feed area prevents jams and ensures efficient waste input.

By keeping up with maintenance, you can prevent major issues, extend the shredder's lifespan, and reduce the likelihood of unexpected breakdowns.

Plastic shredders are powerful machines, and safety is crucial. Proper safety features help prevent accidents and injuries. Here are some important safety features:

Overload Protection: This feature automatically shuts down the shredder if it is overloaded, preventing motor damage or malfunction.

Emergency Stop: An easily accessible emergency stop button allows operators to quickly halt the machine in case of an emergency, reducing the risk of injury.

Safety Training for Operators: It’s important to train all operators on the safe use of the shredder. Knowing the correct procedures for operating the machine, as well as emergency protocols, ensures a safer working environment.

Plastic shredders are essential for efficient waste management, offering cost savings, environmental benefits, and improved recycling. They help businesses recycle plastic efficiently, reduce waste, and promote sustainability.

Investing in a plastic shredder can significantly reduce disposal costs, improve recycling processes, and contribute to a more sustainable future. Businesses should consider adopting shredders for better waste management and cost-effective operations.

A: Plastic shredders help reduce waste by breaking down large plastic items into manageable pieces. They promote sustainability by recycling plastic into new products, reducing the need for raw materials, and lowering environmental impact.

A: Shredders reduce the volume of plastic waste, making it easier to store, transport, and recycle. This helps businesses manage waste efficiently and reduces the strain on landfills.

A: Yes, plastic shredders are equipped with safety features like overload protection and emergency stops to prevent accidents. Proper training and regular maintenance ensure safe operation.