- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 1366 Author: Site Editor Publish Time: 2025-06-13 Origin: Site

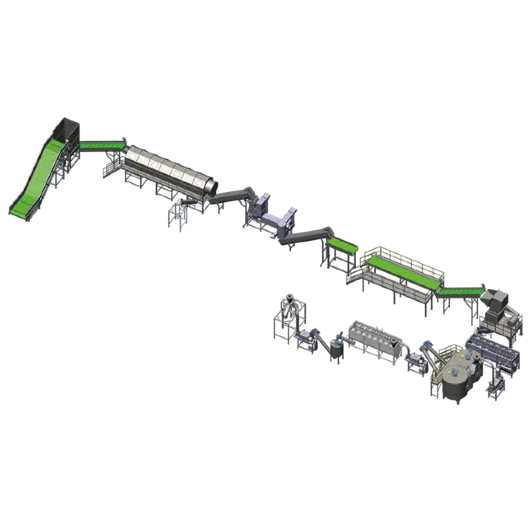

In the modern era, recycling plays a pivotal role in environmental sustainability. One of the critical processes in plastic recycling, especially for polyethylene terephthalate (PET), is the PET washing line. This specialized machinery is designed to clean PET materials, enabling their reuse in various applications, including the production of new plastic products. As global awareness of environmental issues increases, the demand for efficient and sustainable recycling methods is growing, making PET washing lines an indispensable tool for plastic recycling industries worldwide.

This article delves into the concept of PET washing lines, their applications, the significance of these systems in the recycling industry, and the underlying technologies that make them efficient. If you're looking to explore the benefits and functionality of PET washing lines, Changzhou Dyun Environmental Technology Co., Ltd. offers cutting-edge solutions that you can trust.

A PET washing line is a machine specifically designed to clean post-consumer PET waste, which mainly consists of bottles, containers, and packaging materials. This waste material is cleaned through a series of mechanical and chemical processes, ensuring that it meets the necessary standards for further processing or repurposing.

In the context of recycling, the PET washing line has emerged as one of the most critical systems in ensuring that PET materials are properly cleaned and prepared for reuse. The line is not only beneficial for reducing waste but also contributes to resource conservation by enabling the recycling of plastics into new products. By reprocessing PET bottles into clean, reusable material, recycling plants can significantly reduce environmental pollution and reduce the need for new raw materials.

The PET washing line operates through a series of stages, each designed to remove impurities from PET materials. The process can be broken down into several key phases: feeding the raw material, pre-washing with hot water, mechanical cleaning and dewatering, impurity separation, and final washing and drying.

The initial step involves feeding the contaminated PET materials, such as plastic bottles and containers, into the system. This process is crucial, as it ensures that the materials are properly aligned and organized before the cleaning process begins. The materials are typically sorted based on their size and type to ensure optimal cleaning efficiency.

In this phase, the PET materials are soaked in hot water to soften and loosen the contaminants. The heat helps break down adhesives, labels, and other sticky substances that may have adhered to the plastic surfaces. Pre-washing is a critical step as it prepares the materials for the mechanical cleaning process that follows.

After the pre-wash, mechanical scrubbers and washers are used to further clean the PET material. These machines remove dirt, oils, and other foreign substances from the plastic. The PET is then subjected to a dewatering process, where excess water is removed, ensuring that the materials are ready for further processing.

One of the most crucial aspects of the PET washing line is its ability to separate impurities such as labels, plastic contaminants, and other non-PET materials. This is achieved through specialized separation technologies like air classifiers, flotation tanks, and vibrating screens, which ensure that only high-quality PET is retained for reuse.

After the impurities are removed, the PET is subjected to a final wash to ensure that it is free of any remaining contaminants. Following this, the material is dried using hot air or other drying methods, ensuring that it is ready for further use in manufacturing processes.

The efficiency and effectiveness of PET washing lines are largely due to several key technological features. These features not only improve the cleaning process but also contribute to sustainability and operational efficiency.

Modern PET washing lines are highly automated, with advanced control systems that monitor and regulate the entire cleaning process. Sensors and automated processes help to maintain a consistent cleaning quality while reducing human error and operational costs. Intelligent management systems can also optimize production speed and efficiency, allowing plants to scale their operations based on demand.

Energy efficiency is a central consideration in the design of modern PET washing lines. These systems are engineered to consume less water, electricity, and chemicals, minimizing their environmental footprint. The use of heat recovery systems, for example, allows the reuse of hot water, reducing energy consumption.

One of the most important aspects of a PET washing line is its water treatment system. The process of cleaning PET materials typically involves large quantities of water, which can become contaminated with oils, chemicals, and dirt. A well-designed washing line incorporates advanced water filtration and treatment systems to recycle and purify water used in the process. This not only helps to protect the environment but also ensures that the plant complies with environmental regulations regarding wastewater discharge.

Maintaining high cleaning standards is essential to ensure that the PET material is of the highest quality and can be reused for the production of new products. Modern PET washing lines are equipped with advanced monitoring systems that track the quality of the cleaned material. These systems ensure that contaminants are effectively removed and that the final product meets the required specifications for further processing.

Effective management of a PET washing line is critical for optimizing production and ensuring consistent output. The following are essential management points for efficient operation:

Production Scheduling and Process Optimization

Proper scheduling of production runs and workflow optimization are key to maximizing throughput. By balancing input material and ensuring timely maintenance, production can be maintained at optimal levels. Process optimization involves regular analysis of the washing process to identify areas for improvement, reducing downtime and enhancing productivity.

Operator Training and Management

Well-trained operators are vital to the smooth functioning of the washing line. Training should cover both the technical aspects of the machinery and safety protocols. Effective operator management ensures that the team can quickly adapt to troubleshooting, reducing errors and improving overall performance.

Enhancing Production Efficiency and Problem Solving

Increasing production efficiency requires continuous monitoring of key metrics, such as cleaning quality and energy consumption. Promptly identifying and addressing issues—whether mechanical, operational, or related to material handling—ensures that problems do not disrupt the workflow and helps maintain high production rates.

In conclusion, PET washing lines are an essential technology for the efficient recycling of PET materials. They not only play a crucial role in cleaning and preparing PET waste for reuse but also contribute significantly to environmental sustainability by reducing plastic pollution and conserving resources.

If you are looking for high-quality PET washing lines that are energy-efficient, environmentally friendly, and equipped with the latest automation technologies, look no further than Changzhou Dyun Environmental Technology Co., Ltd. With their advanced solutions and expertise in the field, they offer reliable and effective PET washing systems that meet the needs of the modern recycling industry.

For more information on their products and services, visit Changzhou Dyun Environmental Technology Co., Ltd., and discover how their innovations can help your recycling operations.

content is empty!